Though it has always drawn a great deal of attention and rarely fails to mesmerize an audience—both in its function and concept—3D printing has been little more than a means to streamline the prototyping process until the past decade. In that time, we’ve seen numerous types 3D printing technologies create not just prototypes, but viable parts that can be used in functioning machinery applications.

In a recent article, I detailed a number of facts outlining how 3D printing will impact manufacturing in the next few years. From the ability to print parts and components using a number of different materials and deposition processes to the potential effects on manufacturers’ intellectual property, all signs point to 3D printing fast becoming a game-changing technology for industry.

Another sign of 3D printing’s transformative potential for industry came to light in an announcement from GE that it will build a new, $32 million advanced manufacturing facility in Findlay Township, Pa., near Pittsburgh. The facility, according to GE, will focus on improving the capabilities and use of additive manufacturing (aka 3D printing) across GE. Advanced manufacturing activities in which additive manufacturing will play in role in this facility include: digital fabrication technology, lean manufacturing methods and rapid-prototyping, advanced materials sciences, supply chain efficiency, and open innovation.Construction is expected to begin in March 2015 and be completed by September 2015.

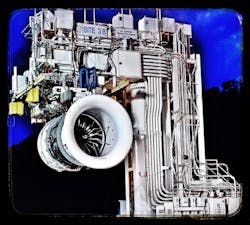

A driving factor behind GE’s increasing investment in additive manufacturing is the payback it is already achieving with the technology. For example, at the company’s Rutland, Vt., facility, a $75 million investment to expand the site for advanced materials use by GE Aviation has led to more than $300 million in engine production savings. And next year, at the company’s Auburn, Ala., facility, mass production begins on the interiors of fuel nozzles for the next-generation LEAP jet engine being developed by CFM International—a 50/50 joint company of GE and France’s Snecma (Safran). Each engine has 20 nozzles (produced by Advanced Atomization Technologies, a GE and Parker Aerospace joint venture) incorporating GE’s 3D-printed interiors that reportedly make the engine more durable, lighter, and fuel-efficient. According to GE, 3D printing allows GE to make the nozzle interiors as one part rather than 20 individual parts, reducing the number of brazes and welds required using traditional methods.

The new Pennsylvania site is the fourth advanced manufacturing facility construction announcement made in the past two years by GE. Previous announcements include the establishment of advanced manufacturing locations for GE Power & Water in Greenville, S.C., GE Aviation in Asheville, N.C., and GE Oil & Gas in Jacksonville, Fla.

Leaders relevant to this article: