In a blog post this past August exploring the differences between fog computing and edge computing, I spoke with David King, CEO of FogHorn Systems (a developer of edge intelligence software for industrial and commercial Internet of Things applications). Despite their product not being available at the time of the interview, I found FogHorn to be worthy of watching because of heavy investment in the business’s technology from industrial companies such as GE, Bosch and Yokogawa.

Because their product had not been released at the time of our discussion, King was unable to divulge many details about FogHorn’s edge intelligence technology; although he did promise the company would offer “a new twist on the process.” Now the product has been released and we can publicize the details.

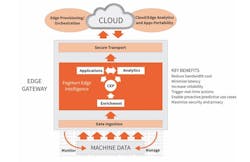

FogHorn’s product is the Lightning software platform for real-time analytics applications. According to the company: “Lightning allows application developers, systems integrators and production engineers to quickly and easily build high-performance edge analytics solutions for their industrial operations and Industrial Internet of Things (IIoT) use cases, and rapidly deploy those applications throughout highly-dispersed distributed edge environments.”

The issue of processing and correlating massive amounts of sensor data in real time is “one of the biggest challenges associated with gaining data insights at the edge” in industrial applications, says Sastry Malladi, FogHorn’s chief technology officer. As an example of how big this challenge is for industry, McKinsey & Company recently reported that less than one percent of the data being generated by 30,000 sensors on an offshore oil rig is currently being used to make decisions.

“[With Lightning] the high bandwidth costs of sending data from thousands of devices in remote deployment locations to the cloud for later processing is eliminated or significantly reduced.Bringing powerful analytics closer to the data source is made possible through our patent-pending, high-performance, small-footprint edge analytics engine and other key technology innovations we have introduced at the data ingestion, data processing and data publication layers of the Lightning edge software stack,” says Malladi.

King noted that one of GE’s “brilliant factories,” which produces industrial-grade electrical products used in power grids, is working with FogHorn to apply real-time analytics for maximizing manufacturing yields from data emitted by hundreds of sensors attached to each assembly line.

“FogHorn’s real-time edge analytics align with our strategy to optimize lean manufacturing and digital capabilitiesin our brilliant factories,” says Anup Sharma, general manager, Digital Productivity, GE Digital. “Our engineers and analysts can work together on applications to analyze data from hundreds of sensors in real time using an extremely agile approach, helping to improve productivity.”

Beyond investments from GE, Yokogawa and Bosch, FogHorn’s partner ecosystem also includes Siemens and Rockwell Automation. The platform works with cloud providers Predix (GE), Microsoft Azure, SAP HANA, Cloud Foundry and Amazon Web Services. FogHorn is also a certified Dell IoT solution partner and the Lightning platform has been validated on HPE Edgeline IoT Gateways as well as other Intel x86 IoT server platforms.

Leaders relevant to this article: