In a previous blog post, The Industrial Internet of Partnerships, I wrote about the increasing number of unconventional partnerships being created to deliver Industrial Internet of Things (IIoT) products and services. And by unconventional, I mean direct competitors working together.

Another unusual IIoT business connection I encountered at the Industrial Internet Consortium’s IoT Solutions World Congress 2016 in Barcelona involves automation technologies directly. This connection relates to MatrikonOPC’s UA SDK (software development kit) being selected by Emerson Process Management for use in its CSI 6500 ATG Machinery Health Protection System. At first glance this may not seem all that unconventional, until you recall that Honeywell purchased Matrikon in 2010.

Although Emerson’s initial use of Matrikon’s OPC UA SDK is in its CSI 6500 ATG protection system, the agreement between Emerson and Honeywell facilitates adoption of Matrikon OPC UA SDK across all relevant Emerson Process Management products. Evaluation for further deployment within Emerson Process Management is ongoing, according to the companies.

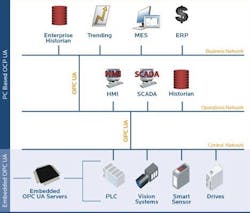

As a widely used data connectivity standard, OPC UA is increasingly being used by device suppliers and OEMs to enable IIoT connectivity in their products. According to MatrikonOPC, its OPC UA SDK is a “single, fully scalable toolkit that allows users to quickly and easily interconnect industrial software systems, regardless of the platform, operating system or size.”

Speaking with Darek Kominek, senior product manager at MatrikonOPC at the IoT Solutions World Congress, he said that MatrikonOPC is targeting open connectivity of devices and systems driven by OPC UA connectivity. “Our toolkit enables vendors with small systems to embed OPC UA communication capabilities,” he said. These systems include various process instruments or even discrete sensors for monitoring machine condition.

When I asked Kominek about this extension beyond the process industries—the usual market for Honeywell—he said: “Honeywell is focusing on software, which means we’re not just targeting the process industries.” He explained the IIoT angle of Matrikon OPC UA SDK as being directed toward end users in plants who rely on multiple different automation systems. “We look at migrating or converting legacy systems to use OPC UA for security reasons as well as its open communication capabilities,” he said. MatrikonOPC also works with vendors during development of new equipment, so that OPC UA doesn't have to be added after the fact.

Noting that MatrikonOPC has been helping vendors embed OPC UA in their industrial devices for the past four years, Kominek pointed out that OPC UA gives its software stack away for free; what MatrikonOPC adds is “a stable tool kit for its application. I like to say it (Matrikon OPC UA SDK) is a drop-in OPC UA server. It’s ideal for vendors who don't know OPC UA but want to offer it in their devices,” which is becoming increasingly popular with the surge in interest around IIoT.

In its announcement of Emerson’s use of its OPC UA SDK, MatrikonOPC said the product works “equally well in small, embedded environments and large, PC-based applications. This scalability makes the SDK a one-stop-shop solution for companies that want to OPC UA enable multiple product lines ranging from networked discrete sensors and actuators to programmable controllers and beyond.”

In the video below, Kominek demonstrates how OPC UA is used to create a digital twin for diagnostics applications. OPC UA is embedded in this demonstration system via use of Matrikon’s OPC UA SDK.

Leaders relevant to this article: