In the past two years, Time Sensitive Networking (TSN) has quickly moved from being a concept for a new approach to industrial communications using standard Ethernet to an IEEE standard poised to transform industrial networking. I say this for three reasons: TSN directly addresses the issues of determinism in industrial Ethernet; TSN enables greater interoperability via standard Ethernet rather than requiring the use of proprietary industrial Ethernet protocols; and numerous automation suppliers, even those aligned with proprietary Ethernet protocols, are supporting TSN.

During a recent meeting with Belden at Rockwell Automation’s Automation Fair, I was alerted to a paper written by Oliver Kleineberg, Axel Schneider and René Hummen of Hirschmann Automation and Control, a Belden brand. This paper details the value proposition of TSN for the manufacturing industries. To support my reasons as to why TSN is so important to the future of industrial networks, I’ll highlight a few of the paper’s key points.

Breaking with Protocol

Before the advent of TSN, if you wanted real-time capable Ethernet technology you would have to commit to using one of the real-time industrial Ethernet technologies, most of which are closed systems to one degree or another.

As stated in the paper: “With some exceptions, these [industrial Ethernet protocol] technologies share a basic compatibility with Ethernet, but the layer 2 real-time communication mechanisms are usually incompatible between the various vendor-specific solutions. As a result, selecting a specific network infrastructure hardware, such as an Ethernet switch, implies a commitment to a particular real-time technology. This, in turn, has the side effect that network operators typically find themselves in a lock-in situation concerning the corresponding vendor-specific ecosystem. The alternative is to accept a patchwork installation of many incompatible systems that introduces a lot of unnecessary complexity in network design.”

According to the authors, these circumstances are “crippling the real-time automation market—a market that…with the emergence of the Industrial Internet of Things (IIoT) and the Smart Factory, has an excellent growth potential.”

The ability to merge multiple data transmissions with the time-critical control traffic on the same network without negative impacts to the network is a major hurdle for any company looking to implement an IoT initiative, such as predictive maintenance. Without TSN, the authors said network operators will find themselves “left between a rock and a hard place,” having to choose a vendor-specific real-time protocol or else be unable to realize the full IIoT potential with conventional Ethernet technology.

By introducing IEEE 802-standardized real-time technology and improving the universally compatible baseline layer 2 communication, TSN enables standard Ethernet to provide a level of determinism that was previously only offered by vendor-specific solutions. As stated in the paper, “By offering the same or better determinism and real-time characteristics, TSN essentially eliminates the necessity to utilize incompatible communication infrastructure hardware and allows merging time-critical and background traffic in a single network.”

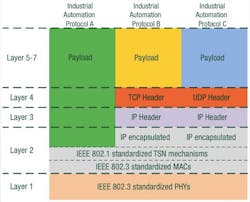

The paper pointed out that the advance of TSN does not equal the demise of industrial Ethernet protocols such as Profinet or EtherNet/IP. “The real value proposition of ecosystems such as Profinet or EtherNet/IP presents itself above the layer 2 network technology in data, device and communication models as well as network and device management functionalities,” noted the authors. “With TSN, all industrial Ethernet ecosystems can utilize the same excellent level of determinism with standardized hardware that is offered by many silicon and device vendors, while maintaining their distinctive characteristics and unique selling points on the application level. Staying within the proven IEEE 802.1 and IEEE 802.3 ecosystem also allows the quick utilization of technical advancements made by these groups, such as bandwidth increases or new physical media.”

Interoperability and Flexibility

Offering an example of how TSN is a win-win situation for both end users and industrial Ethernet protocol suppliers, the paper highlighted work by the OPC Foundation to integrate TSN into its framework using the publish/subscribe communication model. The work being conducted by the OPC Foundation will allow “the configuration of the different mechanisms provided by TSN via an OPC UA configuration model.” This means that OPC UA can combine the features of TSN with its own configuration and management for application of TSN by higher-layer automation protocols in the future.

The paper further explained that “All industrial protocols can benefit directly from the TSN mechanisms that are defined at layer 2 of the OSI reference model. More precisely, the automation protocol can utilize Ethernet frames and encapsulate its payload directly or it can utilize IP and TCP/UDP encapsulation, depending on the given protocol architecture. In addition, managed objects that are defined by the IEEE 802.1 for TSN can be directly mapped to managed objects of the particular automation protocol in order to configure TSN directly with their well-known administration and configuration tools.”

Key to the flexibility of TSN for such varied applications is its modularity. Developers can choose the TSN mechanisms they want to implement depending on the application. “This allows decreasing the overall complexity and configuration of the network as well as to reduce the hardware and software requirements of the affected devices,” said the authors. “When a network is designed with Ethernet switches that have a common TSN feature baseline, the actual device configuration on the switches will define which features of that common baseline are used and which are not used. Through configuration, different zones in the network with different service levels and varying network complexity can be defined. Not all TSN features that are available have to be configured and used—only those that are necessary to fulfill the application requirements need to be considered.”