End users of automation technologies may not always consider the capabilities built into the devices they purchase, preferring instead to focus on the capabilities delivered by their new device once installed. But the increasing levels of connectedness being built into automation devices, as a result of widespread interest in the Industrial Internet of Things (IIoT), is necessitating a higher level of interest from end users in the embedded world of their automation devices.

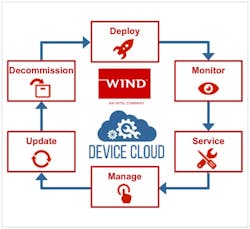

A perfect example of this is the issue of device management. Because IIoT can only generate long-term value for users if connected devices are actively monitored and managed, device management should be designed in as part of an IIoT system architecture to ensure the system’s devices are secure, operational and performing at the highest possible level, said Victor Abelairas, senior director, strategy and operations at Wind River (a supplier of software for intelligent connected systems).

See a recent Automation World report on Wind River’s Titanium Control and how it’s designed to help connect legacy automation devices to the IIoT .

Meeting with Abelairas at the Industrial Internet Consortium’s 2017 IoT Solutions World Congress in Barcelona, he highlighted several key features of Wind River’s updated Helix Device Cloud. This update focuses on bringing added security and privacy to the process of connecting legacy devices for IIoT applications. The new features of Helix Device Cloud include:

- Enhanced Security through zero-touch onboarding for instantly-connected, manageable, hardened devices with Intel technology. The Helix Device Cloud uses EPID (Enhanced Privacy ID) for security, which Abelairas said “forgoes the use of usernames and passwords to enable the use of a unique identifier for each device. With embedded technology—from development to boot to operation to updates—you have to maintain security throughout the entire lifecycle. So, if you can’t update it, you can’t secure it. EPID enables lifecycle maintenance through its registry process. Instead of having to figure out how each device is connected individually and entering that information manually, once you deploy the device and connect it the device falls into the EPID register and receives the appropriate payload of data and is onboarded onto the cloud app.” Like an increasing number of IIoT applications, Wind River’s Helix Device Cloud relies on the use of MQTT for communication with the devices on which it is installed.

- Enhanced Device Management Capabilities via remote monitoring, software over-the-air/firmware over-the-air updates, alerts, rules and data management through the use of IoT technology from Wind River’s strategic partner, Telit (a supplier of IoT modules, connectivity services and software).

- Broad OS support through use of a new Python Agent that simplifies management of a large range of intelligent gateways and devices running different operating systems. “This is important for automation suppliers with multiple product lines,” said Abelairas. “You don’t want different platforms for different devices. You want to manage them all through one interface, which we can do with the Python Agent.”

- Support for public, private and hybrid cloud deployments, as well as expanded regional public cloud hosting options.

- Expanded set of APIs to simplify contextualizing device data and device applications with business processes and business systems.

Given the extensive brownfield nature of industry worldwide, Abelairas was quick to point out that Helix Device Cloud can be embedded in new products at the chip level or used via a gateway in brownfield applications.

Abelairas made note of several companies using the Helix Device Cloud for IIoT applications. Among those he mentioned were:

- Weatherford, an oil and gas services company, which is using the technology via a gateway to harness data from existing artificial-lift system controllers and new wireless sensors to drive oil and gas production insights. Using Helix Device Cloud, Weatherford plans to onboard and manage an installed base of 290,000 wells representing 870,000 sensor data points.

- Bosch has developed an Air Quality Micro Climate Monitoring System (MCMS) for smart cities using the Intel and Wind River technologies to measure air quality. According to Bosch, MCMS offers microclimate data measurements for EPA pollutants including particulate matter, carbon monoxide, carbon dioxide, nitric oxide, nitrogen dioxide, sulfur dioxide and ozone. MCMS also tracks temperature, humidity, light, sound and pressure. With the data compiled, MCMS can analyze conditions and then adjust traffic flow and change emissions at factories and industrial settings.

Addressing how the use of Helix Device Cloud extends beyond technology suppliers and into the realm of OEMs looking to embed this capability into their equipment, Abelairas said, “We’re seeing customers approach this with specific data targeting in mind to see how it can help them more easily provide existing services and cut equipment maintenance costs. Other OEM customers are exploring how to use it for top line growth through the addition of services.”

Leaders relevant to this article: