Over the past few years, 3D printing in the manufacturing world has moved beyond being a point of fascination and into a technology that’s fast proving its worth in applications from prototyping to the production of industrial tools, fuel injection nozzles, gas turbine parts, and pumps. Despite these advances, 3D printing is still considered something of an outlier technology in that it remains far outside everyday, mainstream application in the manufacturing industries.

A recent announcement by Autodesk may impact 3D printing’s trajectory in the manufacturing space.

A few weeks ago, Carl Bass, president and CEO of Autodesk, made a dual announcement around the company’s 3D printing path. Bass announced the release of Spark, an open software platform for 3D printing, which he said will “make it more reliable, yet simpler to print 3D models and easier to control how that model is actually printed.” He also announced the release of an Autodesk 3D printer that will “serve as a reference implementation for Spark. It will demonstrate the power of the Spark platform and set a new benchmark for the 3D printing user experience. Together, these will provide the building blocks that product designers, hardware manufacturers, software developers and materials scientists can use to continue to explore the limits of 3D printing technology.”

Both the Spark software and the design of the 3D printer will be “open and freely licensable,” said Bass.

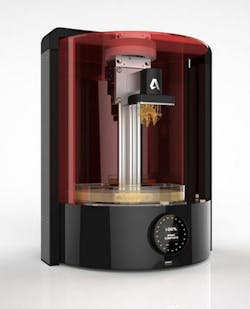

Autodesk’s 3D printer is a stereolithographic printer that hardens liquid plastic with a laser to create objects. In an interview with the BBC, Bass said that, with the Autodesk 3D printer, “rather than just being able to load in proprietary materials, you can load in any material you want. You can formulate your own polymers and experiment with those. That's an important next step because we think material science is a breakthrough that has to happen to make [the industry] go from low-volume 3D-printed stuff to where it really starts changing manufacturing."

In the BBC interview, Bass compared Autodesk’s new printer to Google's first Nexus smartphone, which led other manufacturers to install Android on their handsets. In Autodesk's case, Bass said the idea is to drive the adoption of its new Spark software as an "operating system for 3D-printing".

Forbes reports that the printer will be priced at around $5,000 and targeted at mid-market industrial use.

Considering that Autodesk’s announcement marks a first for 3D printing technology in terms of open source software and hardware application, there are currently more questions about the viability of this approach in the manufacturing industries than there are answers. But the trajectory for the technology’s application certainly seems bright. As IHS pointed out in its recent presentation at Hannover Fair 2014, the key benefits of 3D printing for manufacturing are:

• The additive manufacturing process, wherein materials are added to create a product in 3D printers rather than subtracted, minimizes or even eliminates waste compared to traditional “subtracting” processes to create products. This presents significant potential cost savings to manufacturers.

• Because 3D printed products are designed using computer software and then printed layer by layer, this process allows for the incorporation of features that are not possible with traditional manufacturing techniques.

Read more about what IHS had to say about 3D printing in manufacturing.

Leaders relevant to this article: