If there’s one thing that the Industrial Internet of Things (IIoT) requires—or any industry digitalization effort, for that matter—it is the need for multi-vendor, multi-platform interoperability. No data is shared and analyzed and no systems are connected without it. That’s why organizations like FDT Group and the OPC Foundation, though they may not be household names to most industrial end-users, are at the center of the IIoT, Industry 4.0 and other industrial digitalization efforts.

The FDT Group’s FDT standard establishes an open, modular and holistic automation architecture that adapts to the changing requirements of suppliers and end-users, according to Glenn Schulz, FDT Group’s managing director. Meanwhile, the OPC Foundation’s OPC UA standard provides complete information modeling to connect previously disconnected devices and applications. As Tom Burke, OPC Foundation president, explained it: “OPC UA enables client applications to connect to server applications without understanding the syntax and semantics of the data compiled into the client application. This approach is all about simple discovery of the capabilities of the server, and efficiently leveraging its services and data.”

Since both standards are open, non-proprietary and independent, any automation supplier can use them—and most have been for years.

Explaining how the FDT/OPC collaboration helps ease device interoperability for automation suppliers and, ultimately, end-users, Schulz said that automation suppliers using FDT Device Type Manager (FDT/DTM) technology get the OPC UA interoperability for free—“without any additional work or changes to the DTMs that support their devices.” DTMs are device drivers that allow for connection and configuration of industrial intelligent devices.

“The rich architecture of the FDT specification allowed the added OPC UA integration to leverage existing FDT interfaces with no changes required to the core FDT specification,” Schulz explained. “For end users, this means that their entire catalog of FDT 2.0 DTMs will proffer real-time information to any OPC UA enabled application within the secured enterprise. No additional configuration, downloads, or updates are required.”

The most recent collaboration update from the FDT and OPC organizations came in November 2016 when they announced the released an FDT for OPC UA companion specification for information modeling. “This specification is critical to the standard integration of information provided by FDT technology into the OPC UA information model,” said Burke, “as it provides a key capability for device diagnostics, configuration and remote asset management, as well as for integration with manufacturing execution systems.”

Schulz added that the specification is “intended for implementation by automation system manufacturers in FDT/Frame applications embedded in engineering systems, distributed control systems (DCSs), asset management systems and other applications. The FDT for OPC UA companion specification enables true interoperability between applications and devices for configuration, diagnostics and runtime operation. It allows devices and host applications to easily integrate support with IT applications, including information put into the Microsoft Azure cloud. End-users can implement complete log tracking and tracing of information for all aspects of information management, ranging from configuration to runtime operation.”

I asked Schulz what he meant when he noted that this companion specification enables “true interoperability between applications and devices for configuration, diagnostics and runtime operation.”

“Too often the term interoperability is used to denote basic connectivity or limited common interfaces,” Schulz responded. “In this case, two of the most ubiquitous industrial automation industry standard organizations have come together to ensure a comprehensive integration to address a wide spectrum of industry applications involving sensor-to-cloud to enterprise applications.”

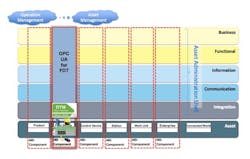

A key aspect of this new specification is the transparency of interoperability it provides to the end user. “When viewed from an architectural perspective, the FDT/Frame has access to all control networks in the facility as well as all supported devices attached to the networks,” said Burke. “It also has knowledge of the complete control system topology. As a result, the OPC UA server in the FDT/Frame allows any client application to browse the topology of the control architecture, select an individual device on any network in the topology, and obtain critical operational data about that device—such as its health, its current output value, its tag information, or other information. The FDT/Frame transparently and automatically handles the routing of traffic across all necessary networks to the OPC UA client, so that it appears that the device is directly connected.”

As an example of how this works, Schulz said that an Android tablet application can be used to act like an OPC UA client to “allow a maintenance technician to ascertain the operational status and health of an asset by interrogating the remote FDT/Frame as he or she roams the facility. To the operator, it will appear as if the wireless tablet is connected directly to the asset in question.”

To further advance FDT Group and OPC Foundation support for IIoT and Industry 4.0, the FDT Group is developing an FDT IIoT Server, referred to as FITS. “It will enable mobility, cloud and fog enterprise applications, as well as sensor-to-cloud and enterprise-wide connectivity,” Schulz said. “It will simplify the move to IIoT by combining OPC UA integration, web services and rich control network interoperability to optimize connectivity and information exchange for the next generation of automation. It will also feature robust layered security addressing all components of the server architecture.”

He added that FITS will be applicable to both greenfield and brownfield applications.

With all the activity in the IIoT device connection space concurring with the development of FITS, I asked Schulz to explain how—or if—the FDT/OPC collaboration and FITS addresses the growth of communication technologies like MQTT and RESTful APIs.

“FITS adds to these existing capabilities by enabling any browser-based clients to access the DTM and server features,” Schulz said. “With REST and WSS, apps can be written that securely access FITS from anywhere in the enterprise or from remote locations. FITS also allows for a fully cloud-based solution and, as such, will support MQTT, VPNs and other means of secure remote access. The good news is that all of the OPC UA integration that is available today will be completely re-usable with the FITS architecture.”

Leaders relevant to this article: