Despite the disruption to business that the pandemic has caused, the Open Process Automation Forum (OPAF) has not skipped a step in its effort to create a collaborative control architecture.

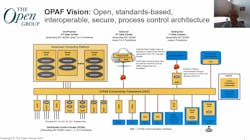

Since the formation of OPAF in 2017, the group—now comprised of around 135 members from suppliers, system integrators, academia, and end user organizations—has been on a mission to design and deliver a modular, scalable, and interoperable framework that can mix best-of-breed technologies and applications from a variety of industrial systems suppliers.

In the past two years the organization has rolled out the first developments of the Open Process Automation Standard (O-PAS)—which is described as a “standard of standards,” as members emphasize that they don’t want to reinvent the wheel, but rather utilize what’s already in use for connectivity, security, systems management, and more. O-PAS version 1.0, released in 2019, specifically addressed the issue of interoperability. Version 2.0, announced last year, focused on configuration portability—the first step toward the ultimate goal of plug-and-play functionality for control equipment, OPAF officials said. In the next few weeks version 2.1 will be released as a preliminary standard.

O-PAS vs. 2.1, announced in February during the ARC Advisory Group Industry Forum, is a continuation of configuration portability and control functionality. This latest version has 12 parts, ranging from definitions of data types, function blocks, alarms, security, and it addresses the IEC 61131 programming language standard and the IEC 61499 standard for industrial automation application portability.

While the march toward a unified standard continues, the proof that OPAF is moving in the right direction comes from the user labs set up across the globe. During the ARC forum, attendees were taken on a tour of three user labs around the world, from the U.S. to the Middle East to Australia. This was one of the perks of having a virtual conference, as attendees were able to get a tour of each of these facilities from the comfort of a home office—and it was interesting!

For example, energy and chemical giant Aramco, in collaboration with Schneider Electric, has built a test bed in the Saudi Schneider Electric Innovation and Research Center in Saudi Arabia. There, they test systems for multi-vendor interoperability, cybersecurity, artificial intelligence and advanced analytics in real-world applications. The University of Western Australia’s Industry 4.0 Energy and Resources Digital Interoperability (ERDi) test lab is working with industry partners on proof of concepts, including how O-PAS will work in the mining industry. And ExxonMobil, together with Yokogawa Electric Corporation, has an open process automation test lab in Texas. It serves two purposes: first, to understand the open system technology with heterogenous parts and develop a design structure, and second, to get it to a field trial. “Even though we did a pilot, it was research, not a production unit,” said David DeBari, a process control engineer at ExxonMobil. The original proof of concept project, which included many OPAF member suppliers like Schneider Electric, ABB, AspenTech, Inductive Automation, ANSYS, and Wind River, was built to demonstrate the feasibility of the architecture to deliver the targeted multi-vendor interoperability through standards without the use of gateways or translators, as well as prove interchangeability between different vendors’ components without having to change the underlying logic.

ExxonMobil, having been the company that initiated this widespread industry movement, very much wants to move to an O-PAS based system. How fast, however, has always been the underlying question. The good news is that there is slow and steady movement in the direction of an open process automation architecture. The bad news is that there is still a long way to go on this journey of designing, testing, and updating the standard. For that, more industry participation is needed.

To that end, OPAF is asking for your feedback—even if you are not a member. They are asking for your stories related to what you are working on and what you need in O-PAS version 3.0. To submit your specific needs, go to: www.cognitoforms.com/opas1/userstories.

Read related articles:

Industry Convenes to Change the Future of Control

Open Process Automation Forum Releases Standard