GE's Intelligent Platforms business has not made a secret of the fact that probably its biggest customer is GE itself. But that’s not to say that it doesn’t have its share of customers outside its own corporate structure, or that the arrangement makes business easygoing. What it means is that Intelligent Platforms' development team has been spurred on my having one of the biggest, most demanding OEMs out there be really tough on them and really honest.

In many cases, Intelligent Platforms' customers become their managers, getting to know so well what they most want from the control, software and analytics that it makes sense for them to take over the reins. After years as chief information officer at GE Energy Storage, Rachel Trombetta just recently took up the position of chief commercial platform leader for Intelligent Platforms.

As she explained during the GE Intelligent Platforms User Summit last month, Trombetta has seen firsthand what data intelligence can do for plant efficiency. She has seen operations improve 10 percent through a single time optimization exercise, for example. In a manufacturing environment where battery cells will fail if pressures and temperatures get too high, she saw how beneficial it was to add more sensors to the machines to look at production on a more granular level.

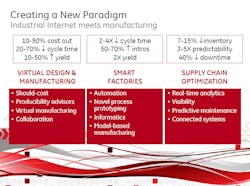

And she has been a major force behind GE’s move to make its factories smarter, combining things like sensor enablement, digital design, and factory and supply chain optimization. “All GE businesses realized they have the same challenges,” Trombetta says, explaining that each business is now tasked with getting two to four of what GE has dubbed Brilliant Factories into operation by next year.

The idea behind the Brilliant Factory is to link design, engineering, manufacturing, supply chain, distribution and services into one intelligent system. The analysis of data from all these disciplines can be used to self-improve products and processes within the system.

“We need to be able to harness all these different data sources,” Trombetta says. Even if efficiency increases by just 1 percent, that can make a huge difference to an operation. GE refers to this throughout many of its presentations as the “power of one.”

The Brilliant Factory relies on key elements of Intelligent Platforms' offerings, including Proficy to look at efficiency and process challenges, Trombetta explains, and Predictivity to better see where they want to get to. Equipment Insights has been able to give operations more visibility into operation bottlenecks also, she adds.

When GE introduced the Brilliant Factory to its battery operation, they went from a 35 percent yield to 65 percent in just a year in a half, Trombetta describes. “Now we’re worried about 95 percent yield.” Sensor enablement was the key to improving quality, throughput and yield, she adds.

As part of the move toward a more digital operation, Trombetta also points to a shift in which IT personnel are becoming a more integral part of manufacturing operations. “IT is really becoming one of the strategic business partners,” she says. “We’re at the table with them.”

Leaders relevant to this article: