Unplanned downtime is not just a costly inconvenience for industrial companies, it can be the difference between business success and failure. That’s why equipment maintenance is often seen as the most critical aspect of business for any industrial company. It’s also why maintenance has been the predominant focus for a variety of Industrial Internet of Things applications — from remote access for equipment monitoring and diagnostics to data analysis for proactive and predictive maintenance.

These trends also help explain why GE has been acquiring maintenance technology companies for years now. Starting with its acquisition of Smart Signal in 2011 for its condition monitoring technology, and continuing through its acquisition of Meridium’s asset management technology in 2016, GE has had a clear focus on equipment management as part of its transition toward becoming a top software company by 2020.

The just-announced update to the company’s Asset Performance Management (APM) suite of software, which operates on Predix (GE Digital’s software platform upon which its own software as well as third-party industrial applications operate), encapsulates GE’s transition toward becoming more of a software and analytics company in addition to its current and historical role as an industrial company with a multitude of high-value assets. The APM update addresses the suite’s Machine & Equipment Health, Reliability Management, Compliance and Integrity Management, and Asset Strategy Optimization modules.

In an interview with Eddie Amos, vice president, applications, at GE Digital, he explained that “this update brings GE and Meridium together in a unified release.” Before coming to GE Digital as part of its acquisition of Meridium, Amos was chief technology officer at Meridium.

Amos explained that this update is referred to as a unified release because of how it combines GE Digital’s asset management technologies though one interface. “The user interface is Meridium, the security is provided by Predix UAA (user account authentication) and the combined data model and case management comes from GE’s APM software,” said Amos. The software suite’s “digital twin technology leverages Time Series (a Predix cloud database service for handling time series data) and Smart Signal components.”

On its own, “Meridium’s issue was accessing all the data embedded in all the asset sources” across a company, said Amos. “Being part of GE allowed us to bring all of that data—like failure codes—into Meridium’s technology. Plus, with GE’s manufacturing experience, we’re able to bring our deep domain and service expertise and define it in the software.”

He added that GE’s knowledge of the asset lifecycle enabled GE Digital to build the APM upgrade “around the asset and tie it together with the digital thread to provide a single view of an asset from both an IT and OT perspective. We have a unique value proposition in terms of our understanding of the technology and the industrial assets.”

Amos noted that “the convergence of OT and IT is where GE is different. Because we design, build, operate, maintain and service industrial machines that operate in some of the harshest environments on the planet, we understand the stages in the industrial lifecycle of equipment like no other company.”

GE Digital is also launching a new analytics practice to review all available asset data, such as seal failures, and triangulate that information back to atmospheric, geospatial and/or design data—or a combination of all three. “Because we manufacture, build and service assets and their supporting technologies, we can combine all these aspects,” said Amos.

Since asset maintenance and reliability has become such a focus for all technology suppliers in the industrial space, I asked Amos how he would characterize GE’s role in the market. He explained that GE’s internal manufacturing expertise with critical assets coupled with its development as a software and analytics company allows for technology development by “GE for GE and GE for the world. Working with this software internally allows us to test out concepts.”

He added that GE’s manufacturing team had been working with Meridium’s software for some time, and that experience “allowed us to build out the product and harden it for the market. GE can be a harder customer than our external customers.”

In its release announcing the software update, GE Digital notes that more than 50 power producers and utilities have committed to using APM on Predix. According to the company, many of these customers are building digital-driven facilities to enhance operations and management of remote sites to better predict and prevent outages before they happen.

The APM update release describes the suite’s components as follows:

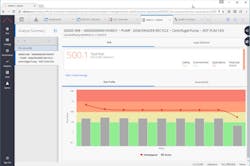

- Machine and Equipment Health offers an always-on, unified view of an asset’s current state and health. With real-time contextual views of asset health, status and issues from the edge, the cloud or a hybrid environment, operators can take action through connectivity to enterprise asset management or other work management systems. The equipment views presented to users are produced by merging data from OT and IT systems, alarms and events.

- Reliability Management provides for less unplanned downtime and more predictable production by forecasting equipment issues before they occur, helping customers evolve from time-based to predictive maintenance, and therefore improve productivity and operator efficiency. Reliability Management also helps to improve workforce safety by identifying bad actors and eliminating potentially disastrous asset failures.

- APM Compliance and Integrity Management helps companies manage risk by monitoring changing conditions through inspection methodologies such as API 580 and 581, and enabling compliance with OSHA 1910.119 Process Safety Management requirements and ISA/IEC standards. Compliance and Integrity Management features a new management of change capability that provides a means for creating and managing change projects, communicating changes and enforcing an approval system to provide implementation accountability.

- The Asset Strategy and Optimization (ASO) module helps users optimize availability, reliability, risk and costs by using intelligent asset strategies to determine the best approach for performing maintenance, inspection or redesign activities. Using ASO, companies can simulate scenarios that most effectively balance risk and cost, allowing them to deploy different strategies in various work management and control systems for complete integration and improved productivity.