Attract Gen Z Workers and Improve Operations with Connected Work Platforms

As more manufacturers aim to recruit Gen Z workers, it’s essential to ensure all instructions are available on their connected digital platforms. Why? Because younger workers are tuned in to search for answers and instructions digitally — so making content available digitally is critical to retain these workers and empower them to take ownership of their role.

From paper to digital device

Frontline workers need content that can be easily and quickly understood and assimilated. That means it needs to be available in multiple formats. But creating all this content in different formats takes a lot of time and capital. Factories have thousands of existing content files, such as standard operating procedures and work instructions. However, converting each one into an easily accessible location can be costly and time intensive.

AI comes to the rescue here by streamlining the creation or conversion of each type of content using AI-powered content transformation to drastically reduce the amount of time it takes to provide digital or written instructions in one secure location.

Video training is key for Gen Z workers

Video is fast becoming one of the most consumed forms of content, especially for Gen Z. So, when it comes to creating digital work instructions, companies shouldn’t overlook the power of video to improve user engagement.

As with conversions of existing documentation into digital files, creating video-based instructions for shop floor workers can be a challenge for factories that lack sufficient financial and human resources.

Here again, AI can help with AI-powered video instructions that creates video content by extracting existing information and sequencing it into structured written steps. Images are added to provide visual context at each step.

This results in the creation of a step-by-side visual guide for workers on how to carry out a task. It also improves operators’ troubleshooting capabilities by giving them access to a broad library of content.

These videos benefit younger workers by providing them the knowledge of senior operators in a way that engages them and meets their new workplace expectations.

Train workers in their native language

Immigrant workers account for nearly three million manufacturing workers in the U.S., and the majority of these workers don’t speak English as their first language. As a result, many manufacturers struggle to ensure their critical operational content is available in all the languages of their diverse workforce.

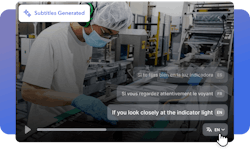

AI-powered transcription breaks down global language barriers and encourages worker inclusion by translating all types of content into the required language. This intelligent capability works by automatically translating the audio from videos into relevant subtitles in the preferred language of the user. This reduces the effort to create and maintain content and improves the comprehension and retention of information leading to better safety, quality and productivity on the shop floor.

Increase hands on metal time and reduce research time

When you’re working in a fast-paced and loud manufacturing environment, errors are naturally going to happen. Here, AI can provide workers with intelligent search capabilities that not only grasps their intent but adapts to human nuances like typos or vague terms. This ensures quick and accurate responses to inquiries like how to troubleshoot a broken mixing machine with a jammed mechanism.

One of the first things Poka did this year was add embedded AI semantic functionality to improve the internal search engine on the Poka app, making it easier for users to find the content they need without needing to scroll through an entire content library. The information used to power this capability sits within the knowledge articles created by the customer and are referenced when searching for answers to eliminate any AI misinterpretations.

Yannick Haeck is vice president of product at Poka.

More Gen Z in manufacturing and connected worker content at Automation World:

Leaders relevant to this article: