Software-Defined Manufacturing’s Potential to Deliver to Automation Interoperability

Developing robust automation and control systems in manufacturing facilities has historically been dominated by proprietary technology stacks. While this offered users highly reliable and deterministic systems, it came with the economic cost of vendor lock-in. High switching costs limited users’ access to state-of the art hardware and software components, while limited negotiating power resulted in non-competitive long-term support agreements.

It also led to a reduced ability to capitalize on emerging paradigms like software-defined manufacturing (SDM), which relies on software interoperability and portability as well as open and modular edge hardware. When built around a standards-based technology framework, instead of proprietary stacks, SDM can be used to exploit state-of-the-art technology insertion or allocate resources to workloads on demand. This can dramatically improve efficiency and increase capacity in a manufacturing environment.

The separation of hardware and software is a key principle of open system design. This means that upgrades to hardware only occur when necessary to support software requirements.

How technology advances enable software-defined manufacturing (SDM)

SDM architectures are based on open hardware and software that is both portable and interoperable. Unlike proprietary systems that are rigid with long component lifecycles, open systems are agile and support shorter component lifecycles.

These software-defined automation systems allow for rapid reconfiguration and low-cost technology insertion. They also provide the ability to create best-in-class application-specific systems using components from multiple vendors. By integrating modular components with an open architecture, organizations can create systems that are flexible and capable of handling future technologies.

The separation of hardware and software is a key principle of open system design. This means that upgrades to hardware only occur when necessary to support software requirements. Generally speaking, in an SDM environment, proprietary single-function hardware and its interconnects are replaced with fewer high-performance, general-purpose multicore platforms that run diverse workloads in virtual machines (VMs) and containers. These can also be built using open, interoperable, off-the-shelf hardware, which eliminates the challenges of vendor lock-in.

SDM is not dissimilar to the software-defined networking shift in datacom that has occurred over the past 20 years. However, to be successful, it requires buy-in from a supplier ecosystem that's been using the same methodologies for decades. The catch for hardware suppliers is that SDM presents risk in that it accelerates the adoption of commodity hardware that will drive per unit margins down. However, this risk also presents opportunities for suppliers to move from hardware-centric business models to ones driven by a commodity hardware-plus-software — and in some cases licensing —approach and its potential for significantly higher margins.

Industry support for software-defined manufacturing (SDM)

There is growing evidence for industry confidence in SDM. Recently, automation suppliers Siemens and Codesys announced the availability of virtual programmable logic controllers (vPLCs) that can be licensed for factory automation applications. Both of these product releases are examples of companies positioning for SDM applications.

Technology frameworks are also being constructed that fast-track the development and deployment of SDM. For example, the Open Process Automation Forum's (OPAF's) Open Process Automation Standard (OPAS) presents an end-to-end stack based on industry standards that speeds development, integration and deployment of SDM-enabled technology infrastructure. OPAS aims to create an interoperable architecture for industrial process automation using existing standards as much as possible.

The InterEdge open systems approach

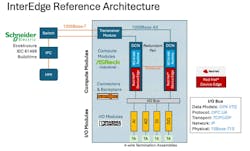

Ratified in February 2024, InterEdge is an open electromechanical and software interface specification from PICMG that is designed to support the interchangeability of industrial-grade compute modules, I/O modules and network switches within an InterEdge ecosystem. Consisting of a modular architecture, InterEdge aims to consolidate the functions of industrial PCs, PLCs, distributed control systems and their associated I/O modules.

Editor’s note: PICMG is nonprofit consortium of companies and organizations that collaboratively develop open standards for high performance telecommunications, military, industrial and general purpose embedded computing applications.

The reference architecture will support an IEC 61499 runtime on top of a Linux OS. IEEE 802.3 and 10Base-T1S MAC/PHYs will be included to support external networking over industrial Ethernet, MQTT, DDS and other protocols.

PICMG InterEdge is foundational to frameworks like OPAS and initiatives like SDM because it offers open, interoperable, standards-based and hot swappable compute and I/O hardware. This allows distributed control systems to access the resources they need on demand. It also helps users transition from one technology, manufacturing process or use case with relative ease.

InterEdge specifies module dimensions, physical interfaces, power buses and mounting details to ensure compatibility and performance. It originated in PICMG as part of the OPAF O-PAS effort. A key differentiator for InterEdge is that it focuses on pluggable modules rather than on board-level interoperability.

More specifically, the reference architecture will support an IEC 61499 runtime on top of a Linux OS. IEEE 802.3 and 10Base-T1S MAC/PHYs will be included to support external networking over industrial Ethernet, MQTT, DDS and other protocols. Reference compute modules will be supplied by ASRock Industrial, while the PCB and connectors are being developed by Samtec. I/O module vendors are currently being identified.

Today, companies such as Exxon Mobil, Schneider Electric, Phoenix Contact, Intel and others are contributing to the InterEdge as the basis of a software-defined manufacturing reference architecture capable of running OPAS-compliant software stacks.

Steve Bitar is automation advisor, ExxonMobil (retired) and chair of the PICMG InterEdge 1.1 Technical Working Group. Matthew Burns is global director, technical marketing, Samtec.

Related software-defined automation and open systems coverage from Automation World:

About the Author

Steve Bitar

Steve Bitar is automation advisor, ExxonMobil (retired) and chair of the PICMG InterEdge 1.1 Technical Working Group.

Matthew Burns

Matthew Burns is global director, technical marketing, Samtec.