Why MES is an Automation Cornerstone in the Processing Industries

Process manufacturing is extremely complex. Operating in a manner that ensures safety, reliability, efficiency and sustainability requires precise orchestration of equipment, people and data to ensure everything occurs within set boundaries.

For decades, the automation industry has been chasing one tool to rule them all — software that would tie the distributed control system (DCS) together with quality systems, human operations, reliability systems and more. For much of that time, the manufacturing execution system (MES) was expected to be that silver bullet, performing all the critical tasks of manufacturing within a single solution.

MES plays a critical role because it executes workflows that tend to be slower and more manual than those driven by other automation systems. It does this while keeping careful records of those activities. But other systems have specific roles to play, too. For example, the DCS is uniquely designed for high-speed, closed-loop control and fast interactions with equipment. Computerized maintenance management systems (CMMS) are effective at cataloging and monitoring. However, when it comes to organizing and streamlining business practices efficiently, an enterprise resource planning (ERP) system is best suited.

In this common processing industry technical architecture, the solution is not to use MES to connect all data sources across the enterprise, but to incorporate the MES as one piece of an enterprise operations platform designed explicitly for seamless integration of critical manufacturing systems.

How MES helps drive autonomy

The benefits of an integrated, modern MES can be seen best in the industries where automation has been applied most effectively. The semiconductor industry, for example, has become the gold standard in how to automate complex, critical manufacturing processes.

A major manufacturer of semiconductors has automated its processes almost to the full extent possible. Decades ago, the company’s most extensive facility required more than 500 operators per line. Today the company has built its newest, most complex facility, which requires fewer than 10 people across the entire plant. In an era where labor shortages make skilled personnel increasingly harder to find, this move toward the semi-autonomous plant is empowering the company’s best workers to do more with less by eliminating the need for them to spend time on low-value, repetitive tasks.

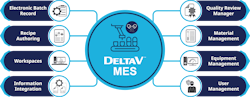

Most advanced automation suppliers are helping users navigate this complexity by building MES software that seamlessly integrates with other key components of their enterprise operations platform, such as the DCS, CMMS and ERP.

MES technology has been a critical element in this move toward semi-autonomous operation. Across any industrial facility, the production process requires a massive number of slow, variable, physical processes, such as moving pallets, scanning barcodes, checking inventory, building kits and signing off on critical stages. Some of those processes can be automated, especially with the increase in robotics, but many remain exclusively manual tasks. And with manual tasks comes unpredictable variability, something that makes these activities hard to code into other automation systems.

When it comes to creating workflows for these types of flexible processes, MES is ideal, thereby making it a critical piece of the automation puzzle. But it remains just a piece. To be a truly effective part of the automation ecosystem, an MES must integrate with the other systems, such as those connecting data, performing high speed control, managing maintenance and equipment hierarchies and performing ERP tasks.

Ultimately, successful deployment of an MES depends on the consideration given to its interoperability with other automation systems. Today’s most advanced automation suppliers are helping users navigate this complexity by building MES software that seamlessly integrates with other key components of their enterprise operations platform, such as the DCS, CMMS and ERP.

MES integration needs standards

The concept of integrating an MES with key automation components is only the beginning, however. Because every organization and industry are different, success with MES technology in one area cannot be replicated simply by copying and pasting the solution into another environment. That’s why industry leaders are coming together to design industry standards that make it easier to connect the MES with other automation technologies.

The solution is not to use MES to connect all data sources across the enterprise, but to incorporate the MES as one piece of an enterprise operations platform designed explicitly for seamless integration of critical manufacturing systems.

An example of this can be seen in Emerson’s One-Click Technology Transfer Board focused on the life sciences industry, whose members include FujiFilm Diosynth Biotechnologies, Merck and Pfizer. The aim of this group is to define reference data models and objects for one-click manufacturing, create the framework for a centralized recipe transport and translation platform that is scalable and extensible, and define and implement standards for version and quality control while ensuring the overall system is easy and intuitive to use.

As executive groups such as the One-Click Technology Transfer Board collaborate to develop a standard translation layer across industries, they can begin eliminating variability, ultimately leading to much less of the manual system integration that consumes extensive time and resources.

Nathan Pettus is president of Emerson’s Process Systems and Solutions.

More insights on MES use at Automation World:

About the Author

Nathan Pettus

Nathan Pettus is president of Emerson’s Process Systems and Solutions business in June 2021. As president, Pettus oversees a business that helps some of the world’s leading companies in a wide variety of industries leverage automation software and technologies to optimize operations, protect personnel and reach sustainability targets.

Pettus received a Bachelor of Mechanical Engineering degree from Tennessee Technological University, a master’s degree in Controls Engineering from University of Texas at Austin and holds a master’s degree in business administration from the McCombs School of Business at University of Texas at Austin.

Leaders relevant to this article: