CMD Uses Embedded PC for Machine Control Logic and HMI On One Device

When an online order reaches your doorstep, it’s imperative that the packaging holds up during shipping. That’s why CMD Corp. implements next-level automation technologies in the design and build of its highly customized converting systems.

CMD (Custom Machinery Design) has manufactured high-speed converting and packaging machines for more than 40 years and is known for its drawtape bag-making technology.

More than a year ago, CMD engineering and product teams started designing the company’s new 1400-GEC mailer packaging machine — a high throughput machine with an intuitive operator interface. The machine produces plastic mailer packaging in a streamlined process, converting film from two rolls, registering the print on those two rolls and slitting in up to five individual lanes of bags. The bags are then packed into boxes using an automated casing management system.

PC-based automation from Beckhoff, including high-precision servo drives and HMI design software, are central to this custom converting machine.

Customer needs drove the 1400-GEC design

The initial concept for this project was driven by specific customer needs, particularly to create bags that would work with automated product loading, said Scott Fuller, product line manager, intermittent motion products at CMD. CMD’s converting customer uses the 1400-GEC machine to produce bags for online retailers, primarily to ship e-commerce items in plastic bags.

By running the entire machine with an EtherCAT-networked CX2033 embedded PC, CMD was able to accelerate the 1400-GEC’s scan times to 2 milliseconds.

“The client approached us as they were seeking to improve throughput in their existing machinery — both their aging equipment and their newer machines that weren’t offering the performance they needed. The customer challenged us to boost their throughput and design a production line that performs up to their standards,” said Fuller.

To address the application requirements, the 1400-GEC unspools two rolls of film, registers the print on those two rolls and applies a continuous longitudinal seal. Then it runs the stacked master rolls of film through a series of cross-directional punches and seals, slits the material into multiple rows of bags, and adds perforation for easy separation. Before loading the finished bags into cases, as specified by the customer, the system performs a vision test while blowing air into the open end of the bag and measuring its shape profile.

“This machine incorporates entirely new automation processes. It transitions from continuous motion to intermittent motion and back to continuous in the outfeed, while handling various tasks in each phase,” Fuller explained. “That makes it distinct from the machines we've designed before.”

All this functionality required significant processing power and real-time communication, for which CMD chose PC-based control and other technologies from Beckhoff. Local application and sales engineers from Beckhoff USA supported the 1400-GEC project with in-depth technical expertise in TwinCAT 3 automation software, motion control and industrial networking with EtherCAT.

Unboxing a new level of efficiency with powerful programming tools

By developing the machine control program in the TwinCAT, everything from PLC and motion control to integrated safety and IoT (Internet of Things) capabilities were able to be addressed in the engineering and runtime platform. A core package for the CMD team was TwinCAT HMI, which allowed CMD to apply modern web design standards, such as HTML5, JavaScript and CSS, in industrial applications.

The CMD team emphasized their need for ease of use and code reusability while designing the new mailer packaging machine. Using the SPT (Special Projects Team) Framework developed by Beckhoff, CMD engineers were able to standardize their code to maximize the company’s engineering capacity moving forward.

Engineers aren’t interchangeable commodities or drop-in replacements. You can’t grab a few off the street, throw them at a problem and expect they’ll be instantly effective.

“Given CMD’s numerous equipment customizations, the SPT Framework — which builds on the ISA-TR88 or PackML standard and the associated libraries in TwinCAT — allows them to create equipment modules for a specific system, reuse those modules in the next customized design and adapt with new modules for the custom pieces of the equipment,” said Don Seichter, area sales manager with Beckhoff USA.

“Our team started working on the SPT Framework in 2018 after watching how long it took engineers to essentially reinvent the wheel by having to write code for the most basic programming aspects,” said Mark Lewis, SPT manager at Beckhoff USA. “Then we released the current, tested version on GitHub for anyone to use for free in 2022.”

The Special Projects Team guided CMD in transitioning to the PackML standard, enabling them to organize programming into different packages. This standard approach to creating code makes it easier for new engineers to work on a project or troubleshoot machinery without decoding what previous engineers may have been thinking when they created it.

“Engineers aren’t interchangeable commodities or drop-in replacements. You can’t grab a few off the street, throw them at a problem and expect they’ll be instantly effective,” Lewis added. “That’s really the biggest benefit of leveraging the SPT Framework: It shortens your engineers’ time to effectiveness. That was a huge advantage with this project at CMD.”

Automation technologies used on the 1400-GEC

CMD’s new 1400-GEC machine uses a DIN-rail mounted CX2033 embedded PC from Beckhoff as the sole machine controller. A dual-core AMD Ryzen processor in the PC enables the machine to execute the machine control logic and operator interface on one device.

“If you're working with a resource-constrained system, your HMI will be very laggy to the touch. So, putting the HMI server on a CX2033, which offers ample computing resources, enables the touch panel to operate very responsively,” said Adam Benson, CMD software engineer.

The EtherCAT industrial Ethernet system and EtherCAT I/O terminals from Beckhoff boosted the modularity, flexibility and high synchronization capabilities that were essential for the 1400-GEC. For example, EK1914 EtherCAT couplers integrate EtherCAT communication with standard and safe I/O terminals to create a space-saving design. The EK1914 offers a mix of standard digital inputs and outputs with several designated for integrated TwinSafe functionality. This allowed CMD to allocate a small amount of functional safety, such as an e-stop, on each tool in the machine line.

“We implemented a fully modern design for this machine, with many stations that accommodate all possible components. The EK1914 adapter provides a compact and cost- effective solution for distributing the I/O and safety hardware closer to the tools,” said Jason Plutz, CMD electrical engineer.

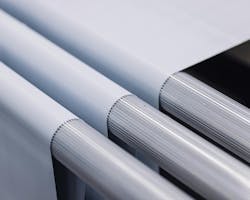

The high level of synchronization provided by EtherCAT also enhanced CMD’s motion- intensive application on the 1400-GEC. The CMD team applied additional performance increases to the 1400-GEC with Beckhoff’s AX8000 multi-axis servo system and AM8000 servomotors to control the machine’s 14 axes. The space-saving design of Beckhoff’s drive technology, such as gap-free drive module installation and One Cable Technology, were major attractions for CMD.

“The AX8000 drives are very compact for the power they provide,” Plutz said. “And by using the integrated safe torque off functionality, we eliminated two large contactors, saving significant panel space.”

To enable unique motion profiles in the 1400-GEC, CMD used camming motion control in TwinCAT 3 software with two of the axes on the bag packaging machine. The bag opener, initially positioned in the intermittent movement section, was relocated downstream to enhance efficiency through the camming functionality. Using a continuous web, the bag opener is precisely cammed to achieve the desired motion at just the right moment.

How Beckhoff automation enabled the 1400-GEC to achieve CMD’s throughput goals

By harnessing the SPT Framework, the CMD engineering team boosted their code reusability to 90%. Employing TwinCAT HMI also helped the team create a more intuitive operator interface in a way that supports customization and reuse.

This machine incorporates entirely new automation processes. It transitions from continuous motion to intermittent motion and back to continuous in the outfeed, while handling various tasks in each phase.

“The new operator interface resembles our legacy HMI, but has a much cleaner, more user- friendly design,” said Benson.

And by running the entire machine with an EtherCAT-networked CX2033 embedded PC, CMD was able to accelerate the 1400-GEC’s scan times to 2 milliseconds. “Having everything scan at one high speed is a huge benefit. You don't have to worry about communicating between process stations that function at different speeds because everything updates at the same time,” Plutz explained.

This enabled the CMD team to reach their target throughput rate of 200 feet of plastic sheet per minute. This translates to 100 bags per minute per lane, resulting in an impressive total of 300 to 500 bags produced every minute.

The CMD team intends to scale up to the CX2043 with a quad-core AMD Ryzen V1807B CPU for even greater machine control horsepower.

Madeline Donkers-Lundquist is social media and content specialist at Beckhoff Automation.

Leaders relevant to this article: