The digital transformation of industry—be it from a general Internet of Things approach or from a more structured Industry 4.0 approach—underscores not only the bulk of current automation technology developments, but industrial business plans as well. From initiatives to connect more plant devices for better analytics to cutting-edge machine learning and artificial intelligence applications, industrial companies of all sizes are gearing up to digitally transform themselves in some fashion.

But such significant changes don’t occur without challenges. Interestingly enough, the most evident stumbling blocks to the digital transformation of industry are not as strongly associated with technologies or expenditures as they are with strategic and operational issues.

According to a new Deloitte Global report, the most significant disconnects between digital transformation plans and actions occur in four key areas: strategy, supply chain transformation, talent readiness, and drivers for investment. Titled “The Industry 4.0 paradox: Overcoming disconnects on the path to digital transformation," the report is based on responses from more than 350 executives in the manufacturing, power, oil & gas, and mining industries. Here’s what Deloitte had to say about each key area in its report:

- The strategy paradox: Though 94 percent of respondents say the need for digital transformation is imperative, only 68 percent see it as an avenue for profitability. According to Deloitte, “Many seem to view digital transformation as a ‘defensive’ investment to protect, rather than grow their business.”

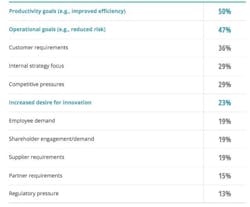

- The innovation paradox: While the digital transformation concept is largely seen as a way of using technology to complete existing tasks more efficiently, Deloitte suggests that businesses should also see it as a driver for investment innovation. “This is increasingly important as organizations stand to be left behind by competitors embracing innovation as the key driver for investment,” according to the report.

- The supply chain paradox: Despite identifying the supply chain as the top area for future investment around digital transformation initiatives, only 34 percent of respondents consider the supply chain to be a driver of innovation. Deloitte contends that this perception is a mismatch with industrial reality and that organizations should more closely align their supply chain functions within broader strategic objectives.

- The talent paradox: Though finding, training and retaining the right talent remains a widely-cited organizational and cultural challenge, the Deloitte report indicates that the more involved an organization is with digital transformation the more likely they are to be satisfied with their organization’s current state of talent. According to the study, “Those that interact with these [digital transformation] technologies on a daily basis believe their organization has the proper talent in place 92 percent of the time, while those who have little to no interaction with digital technology see the greatest gap in talent and development (only 42 percent believe the right talent is currently in place). Since digital transformation deeply affects talent, organizations should stay ahead of talent needs, make upfront investments in talent development, and involve employees in the digital integration process.”