When I think of Italy, I think of art, architecture, fashion, food and wine. I don’t think of a country on the forefront of innovative manufacturing. But that’s quickly changing. In 2016, the Italian Ministry of Economic Development initiated the Industria 4.0 (I4.0) National Plan, a top-down approach that is putting in horizontal methods around advanced technology, education and financing—with the government earmarking €18 billion for the initiative.

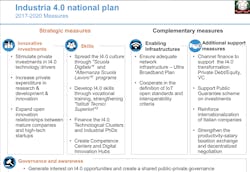

Italy’s I4.0 includes strategic guidelines that are to be implemented by 2020, an effort that will transform traditional manufacturing methods with a focus on skills and advanced technology, as well as support the digitization of the Italian economy. It also emphasizes a future based on collaboration with other countries and even joined forces with other key initiatives, such as the French Alliance Industrie du Futur and the German Platform Industrie 4.0 in an international trilateral cooperation to support and strengthen the digitization processes of their manufacturing sectors. The three countries are bringing together industry, scientists and political experts to focus on standardization, engagement of small- and medium-sized enterprises (SMEs) and testbeds.

The Italian initiative, which aims to attract private investment through tax incentives, concentrates on two main focus areas: it seeks to support the uptake of innovative technologies, helping companies to adapt and digitally transform, grow and increase their competitiveness; and, it focuses on the development of skills through educational programs including digital innovation hubs and I4.0 competence centers

In fact, it was the recent announcement of the opening of the “MADE” competence center in Milan that piqued my interest in Italy’s Industry 4.0 efforts. MADE is a public-private partnership, and this particular center is led by the Polytechnic of Milan and a partner company Comau, an industrial automation and robotics company. MADE will offer SMEs services around orientation, training and support for the implementation of projects for advanced manufacturing.

Comau will support the Milan Competence Center by providing its most innovative products, like the MATE exoskeleton, traditional industrial robots and collaborative robots, the autonomous driving vehicle Agile1500, and the e.DO educational robot.The technologies are accompanied by the know-how of Comau experts for guidance, training and operational support services to companies.

“The participation in the Milan Competence Center - MADE - demonstrates Comau's commitment to innovation and in the implementation of projects capable of contributing to the development of our country's industrial system,” said Mauro Fenzi, CEO of Comau in a statement. “By making its expertise, technologies and advanced processes for Industry 4.0 available, Comau aims to support companies in the acquisition of production processes and tools enabling the smart factory in an increasingly incisive manner.”

Investment in innovation also means focusing on infrastructure, and Italy’s Ultra Broadband Plan is expected to enable access to 30Mbps broadband connections to all Italian companies by 2020, with half of them having access to a 100Mbps connection.

While it may still be too early to tell if Italy’s efforts are paying off. According to information published on export.gov, a website maintained by the U.S. Department of Commerce’s International Trade Administration, “Italy is the second most important manufacturing country in Europe with an extraordinary know-how in strategic sectors such as machine tools, fashion, foodstuffs, automotive and pharmaceuticals. Manufacturing accounts for 23.6 percent of the GDP of Italy. In the current phase of moderate economic recovery, Italy continues to maintain the fifth highest manufacturing trade surplus in the world, amounting to approximately $63.2 billion.”

In addition, the website notes that a recent survey found that over 64 percent of Italian metalworking and machinery companies are now actively applying at least one of the advanced manufacturing technologies, including Internet of Things, additive manufacturing, cloud computing, robots, advanced machine tools and cybersecurity. The website also notes that an estimate by Accenture found that 82 percent of Italian entrepreneurs believe that automation is key to the future of the Italian manufacturing sector.

And so it seems Italy is on a massive manufacturing mission that will create new recognition around the world. Soon, Italy will be known for much more than its fine food and fast cars.