With robotic machine tending applications gaining ground across the discrete manufacturing industries, OEMs, end users and integrators are seeking systems that are easy to set up and install. In response, Mitsubishi Electric developed the LoadMate Plus—a complete robot and stand system that can be configured to fit a variety of applications, such as pick and place, inspection, assembly and packing.

Though the LoadMate Plus was developed with hundreds of pre-engineered configurations for stand-alone cells or integration into larger systems, it can also be customized for unique applications, according to Mitsubishi Electric. Robot options for the LoadMate Plus are Mitsubishi Electric’s CR series, RV-FR series and Assista cobots.

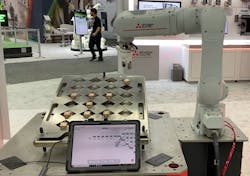

At Automate 2023, Patrick Varley, mechatronics product marketing manager at Mitsubishi Electric, explained that the LoadMate Plus can be programmed via traditional robot programming languages or with a drag-and-drop graphical language that works with Mitsubishi Electric’s cobots and industrial robots. The graphical programming language “makes it very easy to implement straightforward applications for people that are new to robots,” said Varley.

This ease of programming extends even to CNC applications with Mitsubishi Electric’s Direct Robot Control CNC software. Using this software feature, which is part of Mitsubishi Electric’s M8 Series CNC, operators can control and program the robot with menus and G-code from the same screen used for the machine tool with no need to use a robot teach pendant. Mitsubishi Electric said this allows manufacturers to use existing staff to automate and make adjustments on the fly in mill, lathe and drilling/tapping applications.

Another factor that simplifies implementation of the LoadMate Plus is its system integration via Ethernet. According to Mitsubishi Electric, integrating the LoadMate Plus machine tending robot with Mitsubishi Electric’s M8 Series CNC is “as simple as plugging in an Ethernet cable. Discrete I/O is also available for integrating with other controls, making it easy to connect to any machine in the shop.”

In the video below, Mitsubishi Electric's Patrick Varley demonstrates the LoadMate Plus at Automate 2023.

Leaders relevant to this article: