InOrbit Releases AI Copilot for Robot Optimization

July 23, 2024

3 min read

Industrial copilot technologies, which are based on LLM (large language model) artificial intelligence designed to aid workers in their interactions with hardware or software systems, have been a noticeable topic in the automation industry for more than a year, despite the fact that relatively few of them have yet been released for wide use. Learn more about industrial copilot technology.

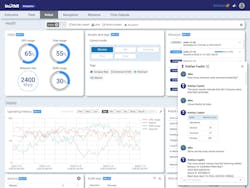

One copilot technology that has made its way to market was announced at Automate 2024, by InOrbit.AI, a supplier of robot operations software. At the event, InOrbit introduced its RobOps Copilot designed to provide operations manager with robot insights to optimize autonomous robot fleets. With RobOps Copilot users can ask questions in their preferred language while using their preferred messaging platform (e.g., Microsoft Teams or Slack) to get detailed explanations of issues, refine their analysis of robots, and arrive at key optimization decisions.

Florian Pestoni, co-founder and CEO of InOrbit, shared an example of how the RobOps Copilot can be used in a typical manufacturing environment. “So, in the Slack chat, the boss is complaining that our orders are taking too long to fulfill. To see what’s causing this, I invite the RobOps Copilot into the discussion channel and ask it how many failed missions we had in the last seven days. With that prompt, I get an almost immediate response that 990 missions failed in that time. Meanwhile, the boss asks the copilot to narrow down those 990 failed missions to just the ones that occurred in a particular location that he knows is part of the issue. That reduces the 990 failed missions down to 97. Then he’s able to narrow down to a particular robot in that location and ask the copilot for a report on it over the last four days. It would have taken a data analyst up to an hour to put together this answer, but the copilot is able to it in seconds.”

Like the main InOrbit Connect platform, RobOps Copilot works with mixed, distributed robot fleets. InOrbit continues to expand the InOrbit Connect ecosystem, including the ability to define, execute and analyze missions that support integrations with warehouse management systems, autonomous mobile robots from different vendors, and goods-to-person workflows. A recent addition to the Inorbit Connect platform is support for Instock’s automated storage and retrieval system. This system is in use at the InOrbit Robot Space in Silicon Valley and is used in the video demonstration below.

Kärcher, a supplier of autonomous cleaning robots, was a beta user of RobOps Copilot. Felipe Garcia Lopez, manager of robotic systems and software at Kärcher, said the interface is “super intuitive, allowing our team to easily find the data insights needed to optimize our robots and drive value for our customers.”

“While there’s a lot of hype about AI and robotics, we’re actually putting the latest developments in machine learning and LLMs to work for real people optimizing real robots,” said Pestoni. “InOrbit RobOps Copilot gives the operations team in warehouses, manufacturing plants or hospitals the power to understand and refine the behavior of their robots, making sense of vast amounts of data without needing a Ph.D. in robotics.”

About the Author

David Greenfield, editor in chief

Editor in Chief

David Greenfield joined Automation World in June 2011. Bringing a wealth of industry knowledge and media experience to his position, David’s contributions can be found in AW’s print and online editions and custom projects. Earlier in his career, David was Editorial Director of Design News at UBM Electronics, and prior to joining UBM, he was Editorial Director of Control Engineering at Reed Business Information, where he also worked on Manufacturing Business Technology as Publisher.

Sign up for our eNewsletters

Get the latest news and updates