As the division between manual production work performed by humans and automated work handled by robots and other equipment becomes less concrete, an array of new tools is coming to market to facilitate this burgeoning flexibility.

Within the past year, we’ve reported on the introduction of the Mate exoskeleton, a wearable robotic technology designed to assist human shoulder movement in production operations; and FT-Produktion’s use of the RG2 double gripper to provide a single robot arm with two “hands” for parts feeding.

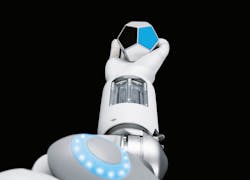

Now, we’ve learned that Festo has developed a BionicSoftHand and BionicSoftArm—pneumatic robot technologies designed to extend human capabilities into the automation realm.

The fingers of the BionicSoftHand are made from flexible bellows structures with air chambers, according to Festo. "The bellows are enclosed in the fingers by a special 3D textile coat knitted from high-strength elastic threads," the company says. "This makes it light, flexible, adaptable and sensitive, yet capable of exerting strong forces.”

Developers of the BionicSoftHand at Festo designed a digitally controlled valve terminal mounted on the hand so that the tubes for controlling the gripper fingers do not have to be pulled through the entire robot arm. This allows for the BionicSoftHand to be more easily connected to other systems and operated with only one tube each for supply air and exhaust air. Proportional piezo valves are used to control the movements of the fingers.

Rather than directly programming the BionicSoftHand like one would with most robotic technologies, Festo has designed this product to learn via artificial intelligence. “Instead of imitating a specific action, the hand is merely given a goal," Festo explains. "It uses the trial and error method to achieve its goal. Based on received feedback, it gradually optimizes its actions until the task is finally solved successfully.”

A 12-sided cube is used in this learning process with the goal of having the BionicSoftHand return the cube to a position in which a previously defined side points upwards at the end the process. Festo says this movement strategy is taught in a virtual environment with the aid of a digital twin, which is created with the help of data from a depth-sensing camera via computer vision and the algorithms of artificial intelligence.

The BionicSoftArm is a modular component of Festo's BionicMotionRobot. Attached to the BionicMotionRobot, the BionicSoftArm can be combined with up to seven pneumatic bellow segments and rotary drives to extend the arm’s reach and mobility, allowing it to work around obstacles in tight spaces. “Direct human-robot collaboration is possible with the BionicSoftArm, as well as its use in classic SCARA applications, such as pick-and-place tasks,” notes Festo in its release about the BionicSoftArm.

Festo attributes the ability of the BionicSoftArm to operate alongside humans as being due to its use of flexible kinematics. The company says this allows the BionicSoftArm to adapt more easily to different tasks in production environments and eliminate the use of safety devices such as cages and light barriers, thereby shortening conversion times.

Leaders relevant to this article: