Advanced Industrial CMOS Image Sensors Deliver Application Benefits

Modern manufacturing and logistics distribution centers need to increase productivity levels by increasing conveyor speeds and widening fields of view and working ranges. However, this is limited by conventional automated inspection and scanning camera systems that use more traditional 4:3 or square format machine vision CMOS image sensors, which have the severe drawbacks of many redundant vertical pixels, and lower frame rates.

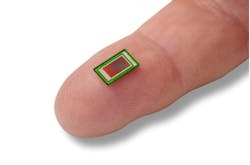

New CMOS image sensors are emerging onto the market, designed especially for scanning applications, representing a major step forward in industrial applications. These sensors use a state-of-the-art, low noise, global-shutter pixel technology and offer electro-optical performances that were barely achievable with a pixel twice its size a few years ago. With a small size and optical arrays that match the mechanical center of the package, slim mobile cameras and modules can be designed, offering powerful solutions, and enabling compact mobile designs for miniature OEM barcode engines, mobile terminals, and sleds, IoTs, contactless authentication systems, wearable devices, drones, and robotics.

Some are available in wide 2.4:1 formats, which makes them particularly well suited for fast-moving objects or barcodes on wider conveyor belts. They can also be connected seamlessly to CPU, ISP, DSP chipsets over 2 lanes MIPI CSI-2 at 1.2GHz.

This new generation of CMOS sensors meets these low-light challenges with small global shutter pixel features and ‘in-pixel’ CDS (correlated double sampling) to achieve a total readout noise of typically 3 electrons. Also, advanced dual light guides with zero-gap micro-lenses maximize the light coupling into the photo-sensitive region of the pixel to achieve good SNR at low light. The light guides and micro-lens also enable a very wide angular response that is closer to a backside illuminated pixel, though these sensors are front side illuminated. These ‘in-pixel’ optical elements also reduce pixel-to-pixel crosstalk to provide crisp images.

Further discussion on image quality needs to cover dark signal and its impact on Fixed Pattern Noise (FPN), especially at high ambient temperatures. High Dark Signal Non Uniformity (DSNU) tends to lead to more visible VFPN/HFPN in the image, even when compensation techniques are used.

Application benefits of Advanced Industrial CMOS Sensors

Currently, the CMOS sensors used for most barcode readers are around 1MP, and equipment manufacturers are competing on price with eroded margins. The arrival of these new scanning-specific industrial CMOS sensors offers an upgrade to enable longer or wider scanning ranges due to their higher resolutions and unique wide formats. This is useful for retail and logistics scanning segments where a larger area/FoV (Field of View) is needed. The end-user benefits from higher-speed conveyor belts and greater throughput compared to existing solutions.

A tiny footprint also makes these new sensors ideal for small OEM scan engines and the thinnest mobile platforms. The combination of a full 2MP resolution, high frame rate, and low power consumption ensures a compact scan engine with higher working ranges and with longer battery autonomy, ideal for handheld and mobile applications. Some sensors also embed specific barcode reading features for fast scanning such as Fast Wake Up to allow the 1st frame decoded in less than 10mS after power is applied.

Document scanning also requires a wide format and is a particularly useful feature in mobile barcode terminals for logistics and parcel delivery.

Future Trends and Applications

Fixed barcode scanners used in retail POS (point of sale) are trending towards object recognition in addition to barcode reading so that fruit, vegetables, and difficult-to-read labels, pass through self-checkouts without intervention and improve the customer’s shopping experience. An RGB form sensor can offer enhanced object recognition and maintain an adequate spatial resolution for traditional barcode reading.

The new high-efficiency global shutter (1/PLS typically >4000 at 660nm) sensors are ideal for general-purpose machine vision applications such as factory automation, automated inspection, etc. These applications used to integrate a square format array but now a Full HD format has become mainstream and some of these sensors can be cropped or 2 x 2 pixel binned in the horizontal direction to achieve this, therefore enabling a single camera design to fulfill all requirements.

The popularity of embedded vision systems has grown significantly with AI and machine learning deployment. These sensors can also be the eyes of these systems.

Other applications for advanced CMOS sensors are in drones or remote IoT cameras because of their small size, weight, and low power aspects. Full HD image format compatibility with 16:9 displays makes these devices naturally suited to remote visual inspection or surveillance applications. Internal temperature sensing is even available to provide additional environmental info and/or enable correction for temperature-related artefacts.

Dentistry can benefit from sensor-based intra-oral 2D or 3D cameras due to their small size. Similarly, color cameras for dental matching applications can also be realized.

A growing area of interest is in medical Point of Care scanning products. These are multi-function hand-held terminals to enable medical examinations to be carried out by patients at home, with their doctor over a video call. The Covid-19 pandemic has significantly boosted this market with the need for isolation and homecare. Cameras are integral parts of these terminals that need to perform a wide range of functions with the ability to zoom up on areas and monitor the progression of post-operation scar tissue for example. Other biometric and metrological tasks are needed to be fulfilled with the same camera, and these scanning-specific sensors are the ideal solution.

About the Author

Arnaud Foucher is a marketing director at Teledyne e2v.