One of the more popular presentations at the Manufacturing in America event in Detroit, sponsored by Siemens and Electro-Matic, was a session titled, “Should We 3D Print This?”

In this presentation, Zach Gray and Adam Hiller of Siemens Additive Manufacturing explained how 3D printing/additive manufacturing has quickly moved beyond its initial use for prototype development and into production of usable parts over the past few years.

Gray was quick to point out that, despite 3D printing’s rapid evolution into production ready parts, the technology “will not replace all traditional types of manufacturing. The value of additive manufacturing (AM) applications depends on the use case,” he said.

AM fits well into the data feedback loop in such systems because of its integration with digital manufacturing tools such as CAD (computer aided design) and PLM (product lifecycle management).

The main reason to produce parts using AM is because they are difficult and/or expensive to make with traditional manufacturing processes.

3D printing makes senses when costs per piece are high or when the part or product has special design requirements that make AM production of the part more economical. Gray noted that the economics of AM are particularly suitable for products manufactured in individualized mass production or when single parts or small series are needed.

“AM can make a significant contribution to meeting market requirements where classic manufacturing technologies reach the limits of technical or economic feasibility,” said Gray.

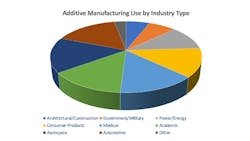

Expanding use across industries

He pointed out that the rapid evolution in use of AM from prototypes to series production means that now is the time to lock down specification and standards to allow for a smooth transition to industrialized AM if it’s right for any of your products.

This expansion of the AM market is expected to reach $10-12 billion in value for the automotive market in the decade, according to USCAR and $6 billion for the aerospace and defense market by 2026, according to Mordor Intelligence.

Gray added that Siemens believes AM is perfect for industry’s increasingly digital environment as part of an end-to-end system that integrates product, production and performance. AM fits well into the data feedback loop in such systems because of its integration with digital manufacturing tools such as CAD (computer aided design) and PLM (product lifecycle management).

Critical part production

Hiller highlighted the eRod by Switzerland-based manufacturer Kyburz as a clear example of AM’s viability in manufacturing. He noted that, prior to using AM, Kyburz had been sourcing model year 1991 parts from Mazda—an obviously unsustainable sourcing process.

When Kyburz began thinking about using AM to manufacture parts for its eRod, they first focused on a wheel hub component. The original part weighed 2.31 kg (about 8 pounds) and the first AM version of that part weighed about same but proved the viability of the AM process for parts production. After experimenting with the Siemens Xcelerator software, the AM-produced part now being used on the eRod is much lighter—1.27kg, a 45% reduction in weight.

“This weight reduction was achieved in just the second version of the part for AM,” Hiller said.” And it could still be optimized further. That’s the fun thing about AM.”

At the 2022 IMTS event in Chicago, Rahul Garg, director of industrial machinery solutions at Siemens Digital Industries Software, said, “The complete digital process provided by Xcelerator enables end-to-end optimization of the part and production process because the digital world is a zero-cost manufacturing environment that can be used to prove out designs and manufacturing processes prior to real world implementation. In this digital world, we can break the part, we can break the machine, we can break the tools and it doesn't cost us anything. We can check everything out before we actually take it to the physical machine—and it’s all done in one integrated environment to ensure there is no data loss and that no problems are possible in any transitions [between one software environment and another].”

Hiller noted that the primary barrier to wider use of AM in industry is due to disconnects between design software, simulation software, print preparation software and AM heat treatment and finishing/inspection processes. This underscores the need to integrate these aspects as part of an end-to-end system to ensure viable AM part production and enable continuous lifecycle feedback.

“Simulation-driven, first-time-right 3D printing is what ultimately determines the value of AM,” he added.