Sustainability scope stages and carbon mitigation strategies are all the rage these days. As statistics grow on environmental imperatives, health concerns and operational efficiencies, it’s a wonder it took us this long to make sustainability a priority. But that’s sometimes how things go. A corporate mandate comes down and everyone rallies around a cry to operationalize an idea that will help move the idea forward—a new project management theory, a new social media platform ot a new cost-savings measure.

We call it innovation and sometimes that title is true to its name, but often it might more accurately be labelled re-invention.

We were asked recently by our partners at Rensenhouse (a supplier of automation and commercial electrical products) to co-present on sustainability. As a full-service engineering firm specializing in controls integration and automation, we dug in deep to the concept of sustainability to identify exactly which piece of the puzzle we at Huffman Engineering could accurately talk about with a high degree of integrity.

What we found not only encouraged us but gave us insight into the sustainability conversation happening right now in industries like pharmaceuticals, water/wastewater, food and beverage, energy and general manufacturing sectors. After all, we’ve been doing sustainable projects for more than 30 years. As one colleague put it” “Huffman Engineering’s been producing sustainable results before sustainability was cool.”

But what does that mean?

A piece of the puzzle

Breaking down core measures of sustainability ratings is one way to go about finding where you fit in the grand scheme of the sustainability puzzle. According to Harvard Business Review, one classification considers four buckets: “Paris compliant” targets and performance, supplier ratings, climate bonds, and environmental, social and governmental (ESG) ratings. At Huffman, we impact the environmental ratings of the ESG model. It’s a small piece of the puzzle, but a significant one none-the-less. Here’s why.

More than 20 years ago, a food processing plant faced high electrical bills. In fact, the demand charges (penalties paid over a 12 month period) were more than 30% of the total bill. So, we took on a project to address energy load shedding (temporary reduction in demand) and load shifting (moving load to off-peak hours).

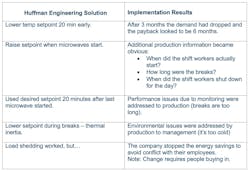

During Phase 1, We monitored primary loads electrical usage by installing power meters and provided trending (consumption and demand) on an HMI for each area. After a couple of months, we could see that the primary demand was coming from the bacon slicing area, specifically when the microwaves were started (300 hp/microwave) at beginning of shifts and after breaks.

Microwaves started within minutes, the room heated up, compressors would load to cool the room and the result was high-demand charges. Load shedding was working, but the company forgot to notify their people, so it was disabled before full gains were realized.

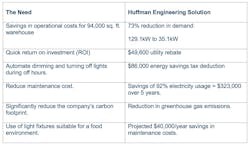

Over ten years ago we designed controls on an LED plant lighting retrofit with sound results for the customer on several fronts, also helping them navigate the significant energy savings through validated documentation and proof of results.

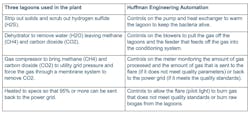

Over the last five years, we’ve done wastewater projects involving digesters and methane gas harvesting. This one resulted in sending 95% of the methane gas back to the distribution system.

Leveraging automation expertise

One definition of sustainability is, “the ability to maintain or support a process continuously over time,” and by that definition for more than 37 years now at Huffman Engineering we’ve been doing our part in sustainably helping our customers upgrade their control systems to reliably support regulated processes for decades. Sustainability is about monitoring and reporting, regulatory compliance, lifecycle assessment, continuous improvement and finding efficiencies in process.

Whether that’s power monitoring for energy savings, methane recapture for reduction in the carbon footprint, retrofitting legacy equipment to find efficiencies in energy demand to lighten the demand on the grid or the electric bill for our customers and communities, we’ve been controlling the systems that regulate draw long before sustainability became the corporate mandate. And we’re proud of that.

When you’re looking for results in efficiency and sustainability, start with a plan and know what you’re trying to achieve. Then look for a trusted, proven, reliable resource in a system integrator to know the software and hardware applications that can get you those results in the most cost-effective and energy efficient manner. If that’s the route you travel on your sustainability journey, alongside a proven partner, you’ll achieve great results together.

Howard Huffman, PE, is founder and president at Huffman Engineering Inc., certified members of the Control System Integrators Association (CSIA). For more information about Huffman Engineering, visit its profile on the Industrial Automation Exchange.