Amy’s Kitchen Boosts Yields and Production with Chef Robotics

Aug. 13, 2024

10 min read

Amy’s Kitchen is a well-known vegetarian food company headquartered in Petaluma, Calif., with manufacturing operations in Santa Rosa, Calif. The company’s 250+ products range from soups and pasta dishes to enchiladas, pizzas, burgers and chili.

Like many food manufacturers, Amy’s saw the demand for its products grow dramatically following the COVID-19 pandemic. And like many food manufacturing operations, Amy’s faced issues with over- and under-depositing of food into its frozen food meal trays. The company’s research into this issue indicated that line workers tended to over-deposit food by up to 12%, thereby decreasing yields for the company.

Amy's also deals with the typical industry workforce issues associated with hiring and retention.

To better manage these operations issues, Amy’s turned to automation, testing an array of equipment ranging from vertical form fillers, depositors and auger-based dispensers to vibratory feeders. The problem Amy’s encountered with these equipment types were that these machines tend work best when used with a small number of SKUs. Also, the dispensers used for liquids don’t work well with the solid ingredients required for Amy’s high-mix production that includes individually quick-frozen ingredients and cooked ingredients.

Frequent changeovers, due to its variety of food products, is also an issue for the company. The automated equipment initially evaluated by Amy’s, such as depositors, typically take three to four hours to break down, clean and re-assemble.

It’s sub-par experience with other automation technologies led Amy’s Kitchen to begin working with Chef Robotics in 2022. Chef Robotics’ flexible automation system features built-in machine learning capabilities, is designed to adapt its robotic pick functions to handle different kinds of ingredients and portion sizes, and its place functions can accommodate different positions within varying kinds of trays on different conveyor setups with quick changeover times.

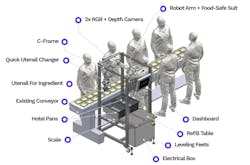

The Chef system is also designed to fit within a human-sized footprint on existing lines so that no redesign of the line is required.

Principal features of the Chef system are:

- Machine learning-based perception: The “Eyes of Chef” is a vision-based perception system that uses machine learning to accurately detect bowl location and food topology for accurate deposit placement and weights.

- Collaborative robots: The robot “Arms of Chef” are chosen for their ability to deliver required throughput while meeting the ISO 10218 industry standard for working alongside humans.

- Proprietary utensils: The end-of-arm tooling “Hands of Chef” allow for easy swapping of utensils to enable Chef to deposit hundreds of different SKUs with quick changeover and minimal sanitation time.

Beyond these built-in capabilities of the Chef system, Amy’s wanted an automated system that could handle two product changeovers per day and more than 10 per week; deliver a throughput rate of 34 bowls per minute per conveyor lane; take less than 10 minutes to disassemble, clean and reassemble each module between runs; and meet Cal OSHA standards for collaborative human/robot operations.

Rajat Bhageria, founder and CEO of Chef Robotics, explained that the Chef system is “productized in that we have one hardware system—a module—that every customer gets. All users get access to the same code base and we have a library of utensils. Based on the customer's ingredients, we'll ship the relevant utensils. The most important part is that each ingredient has its own AI policy of how the ingredient is to be manipulated. And, with Chef’s built-in machine learning, the more we run that ingredient with any customer in the fleet, the better the performance is. Our general premise is to keep the hardware extremely flexible and simple so that it can work with every customer. The software and AI allow us to deal with variances within a particular customer's ingredients, portion sizes, conveyors, trays and placements within the tray.”

Chef Robotics’ deployment approach

“It’s low risk for customers to use Chef because they don’t have to buy new infrastructure,” said Bhageria. “Chef Robotics’ flexible automation system was easily added into Amy’s Kitchen’s conveyor lines because it occupies the same footprint as a single human. All the system needs is a 120V AC power and a pneumatic line with a standard industrial quick-disconnect air coupling, both of which are commonly available in food assembly facilities.”

Since the initial deployment of the Chef Robotics’ system at the Santa Rosa facility in June 2022, the system has been used on up to two shifts a day running a throughput of 34 bowls per minute and accommodating Amy’s Kitchen’s two changeovers per day and 10+ per week requirement.

This increased Amy’s labor productivity during assembly by 17%. Before installation of the Chef system, the assembly line at Amy’s Kitchen required 12 people on average per shift. With two of Chef’s robots, the line only needs about 10 people to operate per shift.

“Amy’s Kitchen can reallocate those original assembly line workers to help with other parts in the plant,” added Bhageria. “This is true for each shift.”

The percentage of food deposits within the desired weight range has improved by 12% overall since the introduction of Chef Robotics to Amy’s Kitchen operations. In some instances, for example, with tofu and carrots, the consistency has improved by 18%.

This has enabled Amy’s Kitchen to reduce product giveaways during assembly by 4% on average for its meals. For example, with the corn and olives ingredient, human line workers tended to over-deposit this by 12% on average, while the Chef system can deposit this ingredient within 1% of the target weight on average, leading to improved yields.

There have also been benefits to food placement aesthetics. The ability of the Chef Robotics’ system to accurately place food into specific quadrants provides a better aesthetic look to the food tray than was possible with traditional automation solutions or even humans. For example, in the lemon rice placement video (below), rice in the top lane was placed by human workers and rice in the bottom lane was placed by Chef.

hef has also benefitted workers’ health in that, before use of Chef Robotics, some of the redundant pick-and-place motions workers had to perform led to repetitive strain injuries and workers compensation claims for Amy’s Kitchen. With the Chef system, Amy’s Kitchen has been able to reduce the number of redundant motions that workers have to do on the line.

Hardware and software

The robot arms used in the Chef Robotics’ system are currently Universal Robots UR5e cobots. “But we've built Chef’s software to be completely hardware agnostic,” noted Bhageria. The end effector is a basic food safe, IP67 pneumatic parallel actuator. As with the robot arms used, the Chef system is built to be hardware agnostic. Bhageria noted that currently Chef Robotics is working with Gimatic for the end-of-arm tooling.

“The utensils are all designed by Chef Robotics and produced by a contract manufacturer,” Bhageria added. “These are part of the core intellectual property of Chef. One way to think about these utensils is that there could be trillions of different ingredient combinations based on how the user cuts, cooks or combines various ingredients. But there are a limited set of utensils per class of food—for example, sauces vs. diced or long materials. The software and built-in AI allows us to deal with the ingredient variances.”

Another feature of the Chef system is its sensor suite and manager dashboard. While the dashboard is machine mounted, Bhageria noted that all the data captured by the system is stored in the cloud so that it can be accessed anywhere in the world via an app.

Bhageria explained that the dashboard “allows users to monitor pick weights on a per deposit level. This is really useful since food manufacturers tend to rely on check-weighers to measure the weight of the full tray. We can measure the weight of each component in the meal. Users can also parse and filter the dashboard in any way they want—per line, per robot, per shift or per hour, per meal, per day, etc.”

The dashboard also allows users to perform line monitoring to assess operations factors such as throughput, line downtime and uptime, and overall equipment effectiveness.

“Amy’s Kitchen now has data on every single deposit made by Chef from anywhere in the world,” said Bhageria. “Amy’s has been able to receive live feedback on its operations status and quickly adjust the deposit weight and placement positions on the fly. Amy’s can now also track historical deposit data via the Chef manager dashboard.”

How AI accelerates food production

The machine learning and AI used in Chef have two key elements, according to Bhageria:

- One of these is used to “figure out where we pick from in a pan of food,” he explained. “Basically, the model takes into consideration the pan topography, the AI policy specific to that ingredient, the recommended utensil and the desired portion size to produce a pick pose in the pan that the robot should pick from to get a good consistent pick at the desired pick portion size. Once the robot makes the pick, we close the loop using the weight we picked—this allows us to improve performance over time.”

- The other element figures out where to detect, track and place the ingredient into the right compartment of a tray. “This allows us to work with different trays, different compartments within the tray, floating inserts—such as a bed of leafy greens, and different conveyor types such as stop and go, continuous or multi-lane without the Chef system having to physically connect to the conveyor. It's all done using vision, which also helps make the system scalable,” said Bhageria.

For both elements, the system is trained on actual production data. “So far, Chef has made 20 million servings in production and these learnings compound on each other,” he added.

Addressing the amount of time it takes to train the Chef system for a new deployment, Bhageria said, it depends on whether the deployment involves an ingredient similar to one we've worked with before or if it’s new to the system. For similar ingredients, he said it takes five to 10 minutes to train for a new setup. For new ingredients or placements, that requires training a new AI policy for that ingredient class which, depending on the complexity, can take days or weeks and may require a new utensil class. For example, the utensil class that works for picking broccoli may not pick up asparagus well.

“To solve the problem with the time it takes to onboard a new class, we're starting to leverage transformer-based diffusion policies and have created a new method to teach the system new tasks,” said Bhageria. “Before, this process required writing code and potentially even designing a new utensil. Now, Chef leverages imitation learning to teach the robot new tasks. This is similar to the technology that powers Sora or DALL-E except that, rather than predicting the next image or pixels, we're predicting the next robot action. We’re on a path towards creating a generalized food manipulation model that the production of 20 million servings of in-the-field production data has made possible.”

Robots-as-a-service model

Because the Chef system is delivered as a service rather than requiring a capital investment up front, Bhageria noted the yearly fee is less than the status quo price of labor.

“The price changes based on factors like number of shifts, complexity of ingredients, throughput required, placement accuracy required, etc.” he added. “The ROI we offer is around helping customers overcome labor shortage issues and increasing production volume, average throughput and product yields while reducing waste and delivering labor savings.”

The robots-as-a-service (RaaS) model offered by Chef Robotics positions the company more like a staffing agency, providing both the hardware and necessary support. “This model eliminates the various challenges of capex by removing the upfront investment, providing transparent pricing and charging a standard annual fee instead of capex add-ons,” said Bhageria. “Additionally, because Chef doesn’t require full line automation, it’s easy to get started and try out four to six robots with a ‘starter pack’ without having to pay hundreds of thousands or millions upfront in capex.”

About the Author

David Greenfield, editor in chief

Editor in Chief

David Greenfield joined Automation World in June 2011. Bringing a wealth of industry knowledge and media experience to his position, David’s contributions can be found in AW’s print and online editions and custom projects. Earlier in his career, David was Editorial Director of Design News at UBM Electronics, and prior to joining UBM, he was Editorial Director of Control Engineering at Reed Business Information, where he also worked on Manufacturing Business Technology as Publisher.

Sign up for our eNewsletters

Get the latest news and updates