Most people recognize Epson as a supplier of printers, ink cartridges, and projectors. Many in industry also know the company as a supplier of high-precision, high-speed SCARA and six-axis robots. What many are not yet aware of is how the company is expanding the reach of its industrial automation technologies.

I learned about the company’s plans while attending an Epson Robots event principally organized for the company’s distributor and system integrator partners. At this event, I got insight into how Epson is not only extending its robot and vision technologies, but also how it’s expanding into industrial wearables and part feeding systems.

To understand Epson’s approach to the industrial market, it’s important to know how the company views itself. The company was founded in Nagano, Japan, in 1942 as an outgrowth of Seiko watch manufacturing. The company’s origins in high-precision watch manufacturing eventually led Epson into robotics in 1983, according to Rick Brookshire, director of robotics product development for Epson. At that time, Epson was looking for high-precision robots to build its watches and could not find the type of robots it needed on the market. This led the company to design and build its own robots, Brookshire said, adding “Then we realized these high-speed, high-precision robots were something the rest of the world would be interested in too.”

This design innovation approach to the market is core to Epson’s “Create, Produce, and deliver,” strategy, said Keith Kratzberg, president and CEO of Epson America Inc. “We do fundamental research and development and are one of the top patent holding companies in the world, with more than 50,000 patents. We develop our own products and produce them in Epson-owned factories.”

Its approach to robot design is to focus on the production of “things that fit in your hands,” said Brookshire. “Our target industries are automotive, consumer, electronics, and medical, with automotive and electronics being two of our biggest markets currently.”

To date, Epson has installed more than 85,000 robots worldwide with a range of integrated options including force sensing and vision guidance. Speaking of these integrated options, Brookshire noted that Epson is not just selling robots in a box, they build solutions. "We have the broadest lineup of light payload SCARA and 6-axis robots to meet specific automation requirements," he said. "And we’re the top supplier of SCARA robots because of our diverse portfolio, which includes more than 300 models with varying reaches and levels of performance and payloads, high-speed and precision, compact footprint, and easy integration.”

Key to understanding the Epson range of robots is knowing its nomenclature. The top end of its SCARA line of robots is the G series, with the T series being its entry level. Likewise, for its 6-axis robots, the C-series is its high-end line and the VT series is its low-cost option. The mid-range for Epson’s SCARA robots is its LS series, and the N series is the mid-range line for its 6-axis robots.

Most of Epson’s robots can be table-, wall-, or ceiling-mounted, but its RS line of SCARA robots is designed to be ceiling-mounted.

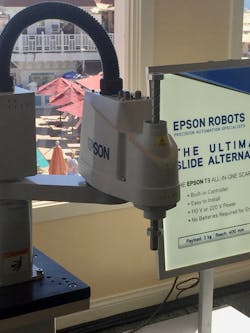

Epson’s T series SCARA robots are made to go head to head against two or three axis linear slides in pick and place, assembly, material handling, or dispensing applications, said Brookshire. “We call the T series an all-in-one robot because the controller is located inside the arm for space saving, and the power unit is built in too,” he added.

This line is available in 220 V or 110 V configurations, meaning it can be plugged into a wall unit in facilities not set up for industrial power. Its motors, amplifiers, and other internal components (such as encoders) are all made by Epson to keep costs down. “Plus, there’s no battery required for these encoders, which reduces total cost of ownership and downtime for maintenance,” said Brookshire. “The only battery on these robots is on the CPU and they have a seven-year life.”

For all lines of its robots, Epson includes its RC+ software. This one development environment applies across all of the company's robot lines, and offers integrated options for vision guidance, parts feeding, force guidance, and conveyor tracking. The software has more than 500 commands and statements for motion functions, I/O control, variables and data types, program control, and more, said Brookshire, adding. “RC+ also features a built-in editor and debugger, and a 3D simulator for fine tuning of applications before setup. The simulator supports up to three robots and can add peripherals, do offline application checking, clearance checking, cycle time calculations, and record and playback functions to show clients as part of quote process.”

Two other software features offered by Epson are Vision Guide and Force Guidance. Vision Guide is a guidance portfolio for standard and high-speed cameras (USB and GigE) that can integrate with Microsoft’s .NET and Epson’s GUI builder. “Vision Guide is ideal for applications like picking parts, assembly, parts feeding, barcode reading, and quality checks,” said Brookshire. It supports up to 20-megapixel cameras and has true geometry-based calibration for SCARA and 6-axis robots.

Force Guidance is built into RC+ for high-performance, precision motion applications, such as parts and connector insertion, screw driving, delicate parts handling, grinding, polishing, and gear meshing for multiple gears. The sensor used on the robot to interface with this software feature is a quartz-based force sensor built by Epson, whose data is fed into the robot’s servo loop to maintain force, Brookshire said.

Epson’s QMEMS technology, which is included in its 6-axis robots as well as its LS line of SCARA robots, is a sensor with gyro servo technology mounted in the robot arm. “The feedback from this sensor ties into the controller to reduce vibration,” explained Brookshire. “It’s proprietary Epson technology that works like noise-canceling headphones to bring precision to smaller robots.”

One new Epson product I learned about at the event was its Moverio smart glasses. Epson has been producing these smart glasses for eight years now for a variety of consumer uses, including drone piloting. Now the company is expanding into enterprise applications with remote assistance software for industrial maintenance and repair support. Available on a monthly subscription basis, the Moverio Assist service enables these augmented reality glasses to connect field technicians with remote experts for real-time “see-what-I-see” video collaboration. Both auditory and visual instructions can be sent by the expert to the glasses to help guide maintenance and repair activities, leaving the technician’s hands free to work. Depending on the Moverio model, the glasses can also store up to 40 GB of photos taken, pdf documents, and video links shared during a call or for direct access after the call, if necessary .

At the event, Epson also highlighted its new IntelliFlex Feeding System, which it is positioning as an alternative to common part feeders available today. Epson partnered with Asyril to create this combined robot, vision guide, and flexible feeder system that eliminates re-tooling to accommodate a variety of parts. “IntelliFlex doesn’t just shake parts, it moves them where they need to be positioned for handling by the robot," said Brookshire. "We designed it this way to address quality and support problems with feeders, slow cycle times, and the typical difficulties encountered connecting robot, vision, and feeder systems. This system has a point-and-click interface, smart auto tuning with robot and vision systems integrated, unique directional vibration capabilities, backlight options—red, green, blue, white, and infrared, electrostatic discharge prevention, anti-static and anti-rolling tray configurations, and support for parts ranging from 5 to 40 mm in size.”

Brookshire added that support for bigger and smaller part sizes will be available soon for the IntelliFlex system. Speaking of features coming soon, there were a few new technology introductions I was briefed on but cannot yet report on due to a non-disclosure agreement. But I can say to stay tuned for more news from Epson around industrial vision and robotic technologies to be released in the coming year.

Leaders relevant to this article: