During its presentation at the ARC Forum in Orlando earlier this month, Bentley Systems announced its acquisition of Acute3D, a company whose software—Smart3DCapture—processes images of existing sites or structures and converts them into 3D models for contextual alignment within design modeling and construction modeling environments. This process is referred to as reality modeling.

A significant portion of the presentation around Acute3D’s technology focused on the use of drones to capture aerial images of sites, such as process industry facilities, and then converting those images into full 3D models. These 3D models can then be used to assure that existing conditions are considered throughout the architecture, engineering, construction, and operation of any infrastructure asset.

It’s important to note here that, although most of the presentation focused on images taken by drones, the presenters stressed that images taken with any device that can capture digital images—including your smartphone—can be used with the Smart3DCapture technology.

“Rather than a voluminous cloud of discrete points, Acute3D produces a 3D reality mesh that is intrinsically in the same geometric idiom as engineering models, readily aligning the real-world context,” says Bentley Systems founder and CTO Keith Bentley.

In terms of how this relates to manufacturing or industrial systems engineering, and not just infrastructure or architectural concerns, consider the potential of applying this technology to production lines. Though this has not yet been done to my knowledge—or even announced—it’s possible to connect the dots when considering the recent integration of Bentley’s point-cloud building information modeling (BIM) with Siemens PLM’s Tecnomatix software for 3D digital factory automation. This integration reportedly enables Siemens PLM users to work from enhanced 3D digital models of existing factories in their as-operated conditions by using the models created from point clouds captured through laser scanning. What Smart3DCapture potentially brings to this kind of application is that, according to Acute3D, Smart3DCapture is a “cheaper, more generalizable alternative to laser scanning … since it requires a simple camera for image acquisition instead of an expansive special device.”

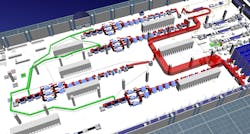

As it relates to what’s available today, the benefits of Bentley’s point-cloud BIM with Siemens PLM’s Tecnomatix integration, according to Bentley Systems and Siemens PLM, include:

- An earlier start of production, by avoiding construction or production line interferences;

- Better quality designs with increased production throughput, reached through accurate simulations of all potential factory layout configurations;

- Rapid creation of as-built plant models, reducing the time and costs associated with modeling the digital factory;

- Ability to use the point-cloud model as the as-built/as-operating record of the line, enabling improvements to operational performance through the factory and product and process lifecycle.

Prior to the BIM and Tecnomatix integration, Bentley’s industrial BIM applications had already been integrated with other Siemens PLM component software tools including Parasolid software, D-Cubed software, and the JT data format.

So, even though it was not announced at the conference, it doesn’t seem that great a stretch to envision the use of technologies like Smart3DCapture in production line applications to capture images for modeling through digital pictures rather than laser scanning. After all, if it can work on large-scale projects, such as process facility images captured by drone photography, applying the technology to automotive, aerospace or even food and beverage production and packaging lines seems simpler by comparison.