Outside of companies that build computing devices, most manufacturing companies—until recently—have viewed software and hardware development as distinct processes. But as virtually every product gains some level of “smart” capabilities, this separation of development processes is dissolving. The focus now needs to be on the seamless development of products with both hardware and software. This reality has left many industrial companies struggling to adopt technologies and processes that are necessary to develop smart, connected products.

Speaking with Ananthakumar Mani, global head of Wipro’s PLM practice, he explained how, in the past, product lifecycle management (PLM) was more focused on the mechanical elements of product development with software “running on a parallel, disjointed thread. The software was part of the bill of material, attached by a .zip or .tar archive to the mechanically oriented BOM.”

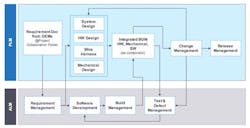

Mani noted that, just as PLM evolved from authoring tools to data and process management, the tools for software development have evolved to support authoring, configuration management, change management, workflow, and other capabilities under the application lifecycle management (ALM) umbrella. And though many PLM suppliers are working with software tools companies to improve the integration of PLM and ALM, it will likely take years before such combined tools become available and are introduced and integrated into production at industrial firms.

To address this gap, Mani said that Wipro has developed a PLM-ALM integration framework based on the following three key principles:

- Linking of data, instead of replicating, between PLM-ALM tools using standards like Linked Data and REST.

- Making the product development process seamless instead of focusing on the capabilities or limitations of PLM and ALM tools.

- A technology agnostic framework to support wide variety of tools.

“At the core of this framework is an integration approach based on Open Standards for Lifecycle Collaboration (OSLC), along with proprietary adapters to allow PLM tools to expose their data in OSLC standards,” said Mani. “This approach focuses on linking data between ALM and PLM tools rather than replicating them. Due to this flexible approach, a seamless product development environment can be set up within existing PLM and ALM tool sets in a company with minimal additional investment.”

Every existing ALM product complies with the OSLC standard, Mani pointed out. He added that, on the PLM side, Wipro’s ALM-PLM integration framework works with PLM tools such as Dassault Enovia, PTC Windchill, Siemens Teamcenter and Oracle Agile. He did note, however, that the framework does not currently support PLM products that do not use service oriented architecture-based web services.

Though the high-tech, medical device, automotive and telecom industries are the primary audience for Wipro’s PLM-ALM framework, Mani said the framework is just as applicable for the industrial/heavy machinery and consumer electronics industries.

Mani said that Wipro’s PLM-ALM framework can benefit organizations by:

* Leveraging current investments by integrating multiple lifecycle tools with minimal effort.

* Providing a single source of truth, as linked data enables data integrity, data traceability, and process consistency across all product definition information.

* Improving productivity by enabling the software engineering approaches of continuous integration/continuous delivery.

During our discussion, Mani could not reveal the names of customers currently using the framework, but he was able to release basic details. For example, he said that Wipro was involved in “envisioning and defining the integrated hardware and software product development process for a medical imaging solutions provider. Wipro deployed its PLM-ALM framework to manage software components from IBM Jazz along with the hardware components in the company’s PLM. It helped in reducing software related defects and improved traceability, thereby reducing the new product development cycle time by up to 30 percent.”

A semiconductor design and manufacturing companydeployed the Wipro integration framework between Rational ClearCase (a computer software tool that supports software configuration management of source code and other software development assets) and the company’s PLM software, enabling integrated bug and change management at the system on chip level. “Wipro helped the customer reduce the chip design time by over six months,” said Mani.

Mani added that a global automotive electronicssupplier worked with Wipro using the PLM-ALM framework to analyze its “as-is software and hardware product development landscape and define its strategy for ALM and PLM-ALM integration to achieve better traceability, improved build management and bridge the gaps between software and hardware product development.”

“Software has quickly become the greatest technology differentiator in today’s complex products,” said Mani. “Without integrating software into the product development process, product launches may easily end in market failures. Adopting a tool-agnostic integrated product development strategy allows organizations to realize benefits in the near term, without having to wait for years.”