For the past 10 years or so, Siemens has been building out its product lifecycle management portfolio through acquisitions, a strategy that has added digital design, engineering and collaboration tools, as well as simulation and manufacturing process management. Last year, Siemens continued to enhance its offering with the addition of Mentor Graphics, a provider of electronic design automation for electronic system engineering and integrated circuits.

The Mentor Graphics acquisition is important as it allows Siemens to address the era of smart products—including phones, appliances, machines, aircraft and automobiles—which have embedded electronics that must factor into the overall design, verification and manufacturing processes.

Autonomous driving, too, is of increasing interest to consumers and car manufacturers alike, which is why Siemens made yet another acquisition last week, adding TASS International to its portfolio. TASS is a provider of simulation software, engineering and test services for autonomous driving, integrated safety, advanced driver assistance systems (ADAS) and tyre modeling.

“TASS is important because it continues to build out our automotive test environment,” said Tony Hemmelgarn, president and CEO of Siemens PLM Software, during a presentation at the company’s industry analysts conference this week in Boston. “It’s expanding our solution offering for simulation and testing the autonomous car.”

The company has been integrating its product portfolio together to create a holistic approach to product design, planning, engineering, execution and services. “We are changing the way ideas come to life,” Hemmelgarn said. It is, what Hemmelgarn called a “systems-driven product development” that provides multi-domain orchestration of electrical, mechanical and software elements to get the true value out of the digital twin. And it is all linked together holistically with Teamcenter, Siemens’ product lifecycle management (PLM), as the backbone. “I see a lot of industrial giants talking about the digital twin, but how could they possibly have one when they have no PLM software?”

To extend the capabilities even further, this week Siemens announced an agreement with HP to accelerate 3D printing for industrial production through the creation of a new HP-certified Additive Manufacturing (AM) software module.

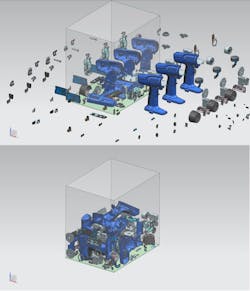

The module, Siemens NX AM for HP Multi Jet Fusion, is now available from Siemens PLM Software as an extension to the company’s end-to-end design-to-production solution for additive manufacturing. The module for NX software—which is Siemens' integrated CAD/CAM/CAE software—will allow customers to develop and manage parts in a single software environment for their HP 3D printing projects, thereby avoiding costly and time-consuming data conversions and third-party tools, and improving overall design-to-finished-part workflow efficiency.

Siemens and HP are also aligning future technology roadmaps to enable designers and engineers to completely reimagine products that take advantage of HP’s 3D printing capabilities and cost-effectively produce new products at faster speeds.

The two companies are working on technology for the next generation HP Multi Jet Fusion 3D printers. “HP understands we are going from one part to mass production of parts, and we are working together on a roadmap of where we want to go,” Hemmelgarn said. “Think about the changes we’ve made over the years. It started with synchronous technology, which changed the way we think about modeling. Then we went to convergent [modeling] and it changed the way were thinking. Now customers are rethinking their process.”

Siemens’ new software module will enable NX customers to combine design, optimization, simulation, preparation of print jobs and inspection processes for HP Multi Jet Fusion 3D printed parts in a managed environment. Users can load multiple 3D part models into NX, and auto nest and submit them to an HP 3D printer, all in a single environment and with a minimum of steps. The NX and Multi Jet Fusion integration also eliminates the need for data conversion between software applications or process steps and, in the future, aims to allow unprecedented control, including material characteristics down to the individual voxel-level. This will result in the ability to print parts with variable textures, density, strength and friction, as well as to offer thermal, electrical, and conductivity characteristics.

Companies could completely transform the way they make products. Now, they just need to shed their conventional methods of manufacturing. “The biggest challenge for us is less about competition, but about customer inertia and getting them to embrace all the technology that is here,” Hemmelgarn said. “But the ones that embrace it and take it seriously can turn it into action to truly create value.”