Industrial Ethernet Advances Broaden the Network’s Value Across Industries

Not so long ago, many doubted that industrial Ethernet could ever take the place of legacy fieldbus on the plant floor. Prior to the rise of deterministic Ethernet communication protocols such as EtherCAT, EtherNet/IP, and Profinet, Ethernet simply wasn’t capable of accommodating the extremely rapid cycle times mandated by complex motion control applications, which often require control loop updates to take place within the space of mere milliseconds to function properly. However, with these issues solved, Ethernet has increasingly become the preferred industrial network, particularly in discrete manufacturing.

According to Michael Bowne, Executive Director at PI North America, four Profinet nodes are now sold for every one Profibus node sold; just a decade ago, those numbers were reversed.

Despite the rise in preference for industrial Ethernet networks, many fieldbus installations remain in place, particularly in the process industries where the shift to Ethernet has been more challenging. One of the reasons for this is that longer cable runs are often needed in large, outdoor environments common to the oil and gas industry. With typical industrial Ethernet being limited to a maximum length of 100 meters to prevent signal decay, this can present an issue. Moreover, with many process industry applications taking place in areas classified as hazardous zones and divisions by the National Electric Code, costly safety measures that require specific expertise must be undertaken to ensure Ethernet cabling and connectors will not ignite a flame.

Recent innovations in Ethernet’s physical layer—the first tier of the Open Systems Interconnection (OSI) model, a conceptual framework used to describe the various functions of a networking system—may help to surmount these obstacles.

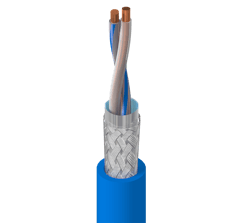

Single Pair Ethernet (SPE) and Ethernet Advanced Physical Layer (APL) are two Ethernet innovations currently leading the way for greater expansion of Ethernet in industry, and both bring with them an assortment of potential benefits. Simply put, SPE is a form of Ethernet that uses a single twisted-pair of wires, whereas other forms of ethernet use two or three. Similarly, APL is a type of SPE combined with IEC 60079 Two-Wire Intrinsically Safe Ethernet (2-WISE) capable of being deployed with pre-existing Fieldbus Type A cabling for use in hazardous environments. While the distinction may seem minute, many industry insiders are hailing the development as having significant implications for industrial networking deployments.

“This is going to be the same type of step change that happened in factory automation when we moved from fieldbuses to industrial Ethernet,” Bowne says. “All those benefits we gained from that—the same thing can happen in process control.”

SPE: Single Pair Ethernet

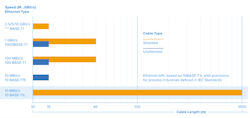

Several qualities possessed by SPE make it ideal for use in process industry environments. First, its maximum length is 1,000 meters—10 times that of previous industrial Ethernet forms. That said, this extension isn’t accomplished without some trade-offs. SPE’s communication speed is 10 Mbit/second, while four- and eight-wire Ethernet can reach speeds ranging from 100 Mbit/second to as high as 10 Gbit/second. Still, this represents a marked improvement over both fieldbus, which has a maximum communication speed of 31.25 Kbit/second, and HART, which has a maximum communication speed of 1,200 bits/second.

In this way, SPE represents a kind of middle-ground between legacy fieldbus and other forms of industrial Ethernet. While fieldbus might not currently offer data transmission speeds that can fully tap the larger quantities of data being produced by Internet of Things (IoT)-equipped devices, four- and eight-wire Ethernet may provide more than is necessary, says Guadalupe Chalas, senior marketing specialist at Phoenix Contact.

“For these field devices, you might need longer cable distances but less bandwidth. So, what happens is if you’re talking about bandwidth specifically, you don’t want to put a standard Ethernet connection of 100 Mbit/second on something that only needs eight or 10 Mbit/second. That would be overdesigned,” Chalas says. “In that case, you’re using an expensive connection on an application that doesn’t need it.”

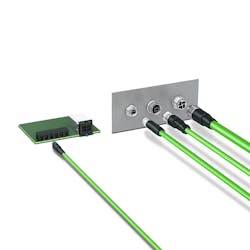

In addition, SPE has swapped the RJ45 connectors native to most Ethernet cables. Not only are SPE’s connectors more rugged, and thus better suited to harsh industrial conditions, but they are significantly smaller and match ports commonly available on existing sensors and other field instrumentation.

"The number one reason that standards organizations are heading in this direction is to ensure greater interoperability," says McKenzie Reed, technology manager for standards development at Harting. "The RJ45 is a commercial product that migrated into the industrial market, and that is what standard organizations working on SPE are putting a ton of time and attention into making sure doesn't happen again because of the quality, compatibility, and performance issues that surround the RJ45 connector when used in industrial environments.”

Finally, SPE enables power over data line (PoDL), which is capable of transmitting up to 50 watts of power over the same twisted pair of wires that transmits data. According to Reed, this can be used to deliver power to small sensors and other forms of simple instrumentation in the field, allowing end-users to further cut costs by eliminating secondary power supplies.

APL: Advanced Physical Layer

APL refers to an installation architecture that can be used to render SPE intrinsically safe for applications in hazardous environments. This is achieved in conformity with IEC technical specification 2-WISE, which defines port profiles for multiple power levels to limit the flow of current in areas where explosions may occur.

According to Al Beydoun, president and executive director of ODVA, while other forms of industrial Ethernet can be used in hazardous environments, they require additional precautions be taken, such as installing mechanical cable protections, using shorter cable runs that must be determined using appropriate calculations, and sheltering connections in additional cabinets and enclosures. By eliminating these needs, APL cuts costs, reduces complexity, and allows for longer cable runs without compromising safety.

Moreover, APL is designed to be compatible with pre-existing Fieldbus Type A cabling, which may significantly ease the process of adoption. This is possible because, while APL is a change to an Ethernet cable’s physical layer, its increased data transmission capacities are enabled by a compatible device’s network interface controller (NIC) and physical transceiver (PHY), rather than the cabling itself. As a result, industries such as oil and gas or wastewater management in which existing cabling may be buried, encased in concrete, or otherwise difficult-to-reach locations can easily make the transition by updating devices and connectors without needing to rip and replace their entire cabling infrastructure.

More data for modern applications

Perhaps the greatest benefit of bringing SPE and APL to process industry applications is the ability to transmit larger quantities of richer, more granular data from sensors and devices to higher level systems due to Ethernet’s greater bandwidth compared to fieldbus. In addition, where fieldbus only offers half-duplex or unidirectional communication, SPE and APL, like other forms of industrial Ethernet, are full-duplex, meaning they can simultaneously transmit data to and from connected devices. With this functionality, real-time, continuous visibility for use in digital twins and other advanced technologies can be made possible.

SPE and APL are also protocol agnostic, meaning that they can be used in conjunction with any other higher-level industrial Ethernet communication protocol, allowing for top-to-bottom Ethernet use without the need for network gateways or protocol conversion that raise costs and increase complexity. According to Reed, this will also make commissioning easier to manage, especially as fieldbus expertise wanes among newer members of the workforce.

However, ubiquitous adoption won’t occur overnight, says Sri Senthamaraikannan, product line manager for industrial Ethernet and electronic cables at Belden. Because devices must be manufactured with the appropriate PHY in order to be compatible with SPE and APL, it could take three to five years before deployment gains momentum. That said, the first SPE and APL compatible devices are going into production this year.

It’s also important to note that SPE and APL are not replacements for, but rather complements to existing forms of industrial Ethernet, and have been designed specifically to bring Ethernet connectivity to select applications, particularly those in the process industries.

“SPE offers many benefits, but it’s not going to [entirely] replace existing four- or eight-wire industrial Ethernet because it still has strong advantages over SPE, such as a higher data transmission rate; but it is definitely going to be the case that SPE will be a cost-effective solution in specific applications where it has an important role to fill,” Senthamaraikannan says. “We see SPE being a critical enabler of adoption of Ethernet in process control environments.”

Companies in this Article

Leaders relevant to this article: