A unit tag is a class-based tag that identifies a characteristic of a unit.

The values of these tags are usually associated with information captured via the control systems analog and digital input cards, signals like temperature, weight, pressure, level, conductivity, pH, level switch, etc. Other unit tags can contain the status, state, material of construction, or any other user-defined attribute that can enhance the recipe editing capability and execution.

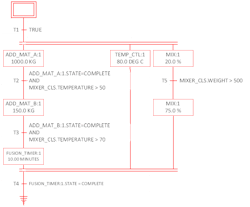

Material A (1000 Kg) should be added while heating (71°C) while slowly mixing (20%), during the addition transition expressions T5 monitors the unit weight to change the mixing speed from 20% to 75% once the weight in the unit is greater than 500 Kg (Unit Weight – Unit Tag).

As per transition expression T2, material B (150 Kg) should only be added after material A addition is complete and the content of the unit has reached a temperature greater than 50°C (Unit Tag – Unit Temperature).

As per transition expression T3, once the material B addition is complete, we need to start a 10-minute fusion timer but, only if the material in the unit has reached a temperature greater than 70°C (Unit Temperature – Unit Tag).

After the fusion timer is complete the recipe will stop controlling temperature and agitation and then move on to the next operation.

Other examples of unit tags can be:

- CIP supply and return conductivity, temperature, flow.

- Thermal lethality factor (F0).

- Total volume or weight transferred.

- Etc.

Unit tags can be used for equipment selection (unit attribute binding) during control recipe creation such as:

- Material of construction (plastic, stainless steel, glass lined, etc.),

- Unit status (To be cleaned, clean, sterile, sterile expired, clean expired, ready, disabled, etc.)

Unit Tags are very simple to implement during the automation setup process and should expose all pertinent equipment information, since they provide the recipe author the capability to condition the procedural activities based on process conditions as well as equipment status.

Randy Otto is CEO of ECS Solutions, a certified member of the Control System Integrators Association (CSIA). For more information about ECS Solutions, visit its profile on the CSIA Industrial Automation Exchange.Leaders relevant to this article: