As the digital transformation of industry drives advances in plant floor Ethernet technology, some automation professionals are wondering about the effect this could have on existing network infrastructure. In particular, the IO-Link system.

If you’re not familiar with IO-Link, it is a standardized I/O (input/output) technology (based on IEC 61131-9) for communication with industrial sensors and actuators based on the established 3-wire sensor and actuator connection. Though the IO-Link system is popular in Europe, it is still relatively new to the U.S. market and is growing in acceptance here due to the ease of connectivity it provides to end users, system integrators, and OEMs.

To learn more about IO-Link, listen to this episode of the “Automation World Gets Your Questions Answered” podcast series or visit this article based on the podcast.

One particular plant floor Ethernet advance stirring questions about its potential use with IO-Link is SPE (single pair Ethernet). SPE differs from standard industrial Ethernet in that, instead of using four or eight total wires, it uses just two wires—a single twisted pair which provides communication across the common industrial Ethernet protocols (e.g., EtherNet/IP, Profinet, EtherCAT, etc.). It uses Power over Data Line technology to deliver the voltage and amperage needed to power the device itself in addition to communications.

In a recent paper developed for PI North America (the U.S.-based unit of Profibus/Profinet International) and written by Hartmut Lindenthal of Pepperl+Fuchs, Dmitry Gringauz of Banner Engineering Corp., Frank Moritz of Sick, and Dr. Franz-Otto Witte of TEConcept, key concerns around IO-Link’s viability with SPE are addressed.

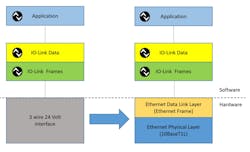

The authors note that the IO-Link-over-SPE concept enables IO-Link messages to be packed into Ethernet frames and then transferred via an SPE driver over a twisted-pair line, rather than having the IO-Link messages transferred as pulse-encoded telegrams over the classic 3-lead cable at 24 V. In this manner, IO-Link essentially remains IO-Link. As such, integration into higher-level systems would also remain the same, with only the communication medium being changed.

One point in particular the authors take pains to note is that IO-Link over SPE is “not another Ethernet-based bus system. Just like standard IO-Link, it is a point-to-point connection without addressing. All the defined interfaces and functions are retained,” they say. “Established IO-Link integration standards like IODD, the OPC UA companion standard, JSON mapping, and fieldbus integration can still be used in the exact same way. In combination with the IO-Link Safety Profile, safety-oriented applications can also be implemented with IO-Link-over-SPE.”

Another factor enabling the ease of IO-Link and SPE integration is that a complete IO-Link message fits into each Ethernet frame or in the user data. According to the authors, the IO-Link message is usually considerably shorter than the data length of an Ethernet frame. In the paper, the authors say: “The resulting cycle time for exchanging Ethernet frames—and thus IO-Link messages as well—is still considerably shorter than with standard IO-Link due to the transfer rate of 10 Mbps. The method for embedding the existing IO-Link message structure into an Ethernet frame is the main idea behind IO-Link-over-SPE.”

Migration concerns

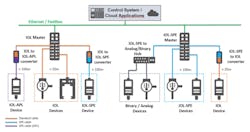

The process of integrating an IO-Link-over-SPE system into an existing IO-Link network structure does not create any issues. The authors say: “There aren’t any noteworthy differences other than the replacement of the standard 3-lead cable with the twisted-pair SPE cabling.”

An added benefit is that the potential distance between the master and IO-Link device increases to more than 100 m (maximum 1,000 m) with the SPE system.

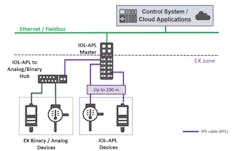

Intrinsic safety affects

As with the migration process noted above, the basic structure between an IO-Link master and terminal devices in an intrinsically safe environment is identical to the existing structure in the environment with standard IO-Link. In this case, however, an APL (advanced physical layer) version of SPE interface physics would be used, limiting the distance between the master and terminal to 200 m. The IO-Link APL master handles the intrinsically safe separation of the power supply and communication with the higher-level system.

Despite its advantages, the authors do not expect IO-Link-over-SPE to replace the standard IO-Link interface any time soon. In the paper, they point out: “As of today, IO-Link-over-SPE is a concept study which points out opportunities for increased performance in conjunction with a considerably broader application focus. An SPE interface in an IO-Link terminal device will also result in higher costs as compared to the standard for the foreseeable future. For this reason, the existing 3-lead, 24 V-based IO-link interface will still be used for the large number of existing cost-sensitive applications. IO-Link-over-SPE can be seen as a consequent extension of the IO-Link standard with lots of potential for the future.”

Leaders relevant to this article: