IO-Link Gets North American Support Community

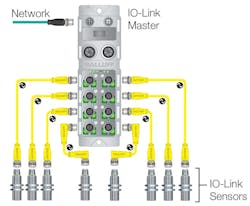

IO-Link has been growing quickly in North America, largely due its use as a key enabler in industry’s digital transformation. If you’re not familiar with IO-Link, it is the first standardized I/O (input/output) technology (IEC 61131-9) for communication with industrial sensors and actuators based on the established 3-wire sensor and actuator connection. It’s been popular in Europe, where it was first introduced in 2006, for many years now.

Two initial drivers behind the development of IO-Link were to enable diagnostics from 4-20mA analog signals and to help standardize cabling in systems that use devices with cables housing anywhere from two to six wires.

To help further adoption of IO-Link in North America, PI North America, the non-profit member-supported trade association for promoting industrial networking technologies in North America, has signed a contract with the IO-Link Community, on behalf of the Profibus Nutzerorganisation (PNO) to become a Regional IO-Link Interest Group (RIOLIG) for North America.

Since IO-Link is so well-known as vendor agnostic technology, i.e., it is not specific to any industrial protocol, we asked Bowne about PI North America’s interest in driving this RIOLIG given their direct work as a promoter of Profibus and Profinet industrial networking.

“Our role is to promote IO-Link usage with any and all protocols—not specifically Profibus or Profinet. In fact, we signed an agreement with the IO-Link Community to this effect,” said Bowne. “When we promote IO-Link, we avoid calling out the higher-level protocol to which it might be connected. A few exceptions to this would be where the protocol isn’t a traditional fieldbus/Ethernet or doesn’t have competitors. For example, we’ll promote IO-Link connecting to OPC UA, or connecting to JSON/MQTT. Ultimately PI North America benefits when a company joins our organization to gain access to the IO-Link technology; we don’t necessarily benefit vis-a-vis the traditional promotion of Profibus/Profinet.”

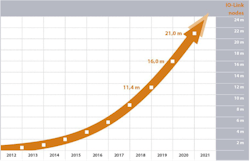

Though no, specific data on the growth of IO-Link in North America is yet available, IO-Link nodes grew by 31% in 2020 over 2019, reaching 21 million nodes.