EtherCAT Plays a Role in Multiple Industries

Timing is everything—especially when you’re coordinating a mix of lights, lasers, pyrotechnics and large moving objects that share the stage with live performers. That’s why, earlier this year, Image Engineering of Baltimore became the 7,000th company to join the EtherCAT Technology Group (ETG), the Nuremberg-based organization that manages and supports the EtherCAT (Ethernet for Control Automation Technology) industrial networking protocol.

For Image Engineering, the benefits of EtherCAT are found in the special effects that it builds for clients ranging from NFL teams to performing artists.

The PC-based automation controllers that Image Engineering obtains from Beckhoff Automation have the intelligence to coordinate pyrotechnics and moving objects safely. The controls also enable complex user interfaces using Beckhoff’s TwinCAT human-machine interface (HMI) software.

“The flexible topologies and interoperability of EtherCAT-based technologies give us the adaptability and reliability we need to integrate our special-effects systems efficiently,” says Dick. “And Failsafe over EtherCAT [FSoE] allows us to incorporate the most important parts of our special-effects units, the safety systems, into the same cabling and software we use for network control.”

Wide applicability across industries

Though an entertainment company like Image Engineering is not a manufacturer, like readers of Automation World, their application of the technology underscores its wide applicability.

What is EtherCAT?

The primary difference between EtherCAT and other industrial Ethernet protocols is that EtherCAT does not use IP (internet protocol) addresses or switches. It operates on standard Ethernet at the physical level, but uses Ethernet in a way called “Ethernet-on-the-fly.” This name comes from the fact that individual nodes on the network need not receive the entire frame before processing it.

“An Ethernet frame using EtherCAT data travels through each node on the network the same way every cycle, and every node extracts and inserts its data on-the-fly,” explains Trask. “As the system initializes, the controller goes to each device and asks, ‘What are you reading and writing?’ Then, it determines the location of that node’s data within the frame. This is the logical process image and it is highly optimized and predictable.”

Because each device processes data as it passes through, processing it on the fly, dedicated switches and complex network configurations are unnecessary. This helps eliminates unnecessary communication delays as well as hardware costs.

As a device-level protocol, EtherCAT is not intended to be a mechanism for communications to systems such as ERP (enterprise resource planning), MES (manufacturing execution systems) or cloud and edge systems, according to Trask.

An appealing aspect of EtherCAT for many users is that devices on the network can be daisy-chained in line, tree, star, drop and other cabling topologies. Sub devices are connected in a series along the Ethernet cable. “This simplifies the wiring process and lowers the overall cost of the network infrastructure,” says Jafari.

Industrial application examples

EtherCAT’s fast cycle times attracts users like CMD Corp., a converting and packaging machine builder. CMD specified EtherCAT when it redesigned its 760-SUP stand-up pouch system last year. One section of the machine runs in continuous motion to feed and fold incoming plastic film while another section runs in intermittent motion to perform sealing and zipper crush operations.

That platform also had a limited I/O speed. “The minimum I/O delay we could achieve was 6ms,” says Plutz.

To overcome these limitations without incurring excessive costs, CMD replaced the 760-SUP’s legacy platform with EtherCAT and Beckhoff Automation’s CX2033 embedded PC as the machine’s controller. The CX2033 runs at only 15% load on just one of the controller’s two processor cores.

Making this change also allowed CMD to eliminate a high-speed I/O module from a punching operation. In the past, a gusset punch on the continuous side of the machine required the additional hardware and excessive engineering to synchronize actuation with the position of the material. “Now, the standard I/O on EtherCAT is fast enough for our application,” says Plutz.

Fast communications associated with EtherCAT-based systems also caught the attention of Husky Technologies, a manufacturer of injection-molding machines, molds and hot runners. The company uses EtherCAT on the control platforms for both its injection molding machines and its hot-runner systems.

Husky first adopted the technology in its production machines in 2008, adding it to the Profibus communications already in use to create a mixed fieldbus network. The goal of adding EtherCAT was to boost performance by running some parts of the machine with a scan time of 250μsec.

Massive network support

Another advantage of EtherCAT’s design is that networks based on it can be massive.

“Some fieldbuses are only strong enough to accommodate about 250 nodes before needing to add another network,” says Jafari. “EtherCAT can have up to 65,535 nodes in one network.”

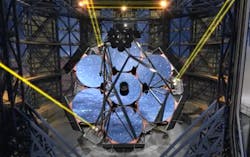

The observatory’s control system will coordinate more than 3,000 axes of motion to rotate the telescope’s 22-story enclosure and adjust the position of its seven mirrors, which have a combined diameter of 25 meters.

“It’s a complex machine with thousands of degrees of freedom that need to be controlled with various levels of precision, some loose and some extremely accurate,” notes José Soto, senior electronics engineer at the GMT Organization (GMTO).

EtherCAT was selected as the GMT’s fieldbus because of its flexible topology, scalability and ability to connect a multitude of devices. A key feature for GMTO is a master sub device architecture.

The architecture also streamlines collaboration among GMTO’s subsystem and instrument teams. “No matter what their designs are,” says Soto, “as long as the teams follow the EtherCAT master sub device architecture, we can integrate them with the rest of the observatory components.”

This ability helps with testing prototypes. “We can quickly set up a bus coupler and some I/Os, close the loops, take measurements and decide how we will implement the production units,” says Soto.

EtherCAT History

Although EtherCAT has been around for 20 years, its roots extend more than a decade earlier than that. The industrial networking protocol evolved at Beckhoff Automation from two older technologies, Lightbus and CANopen.

“EtherCAT’s developers had 15 years of experience tweaking Lightbus on how cyclic traffic behaves” (see the logical process image for reference), says ETG’s Trask. “Their experiences with CAN provided a commonly used state machine and made use of existing CAN objects.”

Beckhoff Automation applied its experience with these two protocols to IEEE 802.3 Ethernet once the use of Ethernet in industrial environments began exploding in the early 2000s. It pursued an approach that would avoid unpredictable Ethernet switches and the complications of IP routing. The result was EtherCAT, which the automation vendor released at Hannover Messe in 2003.

That same year, Beckhoff Automation formed the ETG as an independent trade organization for managing the development of the protocol and promoting its adoption. The organization was formally launched at the SPS 2003 event in Nuremberg with Beckhoff Automation and 33 other companies as founding members. Today, there are more than 7,000 members. “Every member, including Beckhoff, has one vote when decisions are made,” explains Trask.

Despite subsequent development of extensions for such things as safety and gigabit Ethernet, the base technology has remained unchanged. “After two decades, EtherCAT is still on Version 1,” says Trask. This stability allows users to put any current device in a network built in EtherCAT’s early days. It will still work.