Edge computing—where computing devices are located on or near industrial equipment to allow fast capture of their data for onsite or cloud analyses—has been a fast-growing trend across industry. Despite the technology’s relatively straightforward purpose and application, many in industry still have plenty of questions about it.

In fact, during a survey of the Automation World readership, several respondents had questions about the best way to integrate edge computing devices with legacy automation equipment. To learn more about this, we connected with Josh Eastburn and Benson Hougland of Opto 22, a supplier of industrial controllers, I/O, and software, for a recent episode of the “Automation World Gets Your Questions Answered” podcast series.

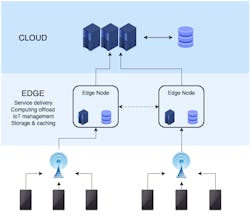

Before delving into the integration details, Eastburn noted an important difference between edge computers and traditional control devices. “Traditional automation devices have been used for data collection, but transmission hasn’t always been so easy,” he said. “With edge computing, we’re talking about systems that can participate in data exchange with IT systems and IT data formats—things that are not native to OT [operations technology]. Edge computing can play in both arenas to connect OT layers to IT layers natively without middleware.”

Eastburn added that, regardless of edge computing’s added advantages, things like ruggedness, agency approvals, and fault tolerance still matter when assessing edge computing devices for use in an industrial setting. And as you look at the bigger picture in industrial automation systems—with the shift in architecture moving toward greater distribution of resources and cooperation between those resources—the edge devices that enable this need to be open because interoperability is key, he said, adding, “But they also need to be secure. And with edge devices we’re seeing a degree of security that hasn’t always been present in traditional automation equipment.”

Hougland explained that we’re seeing these higher levels of security with edge computing technologies on the market because users need programming and data format flexibility at the edge because [edge computers] are built on the standard computing platforms—processor architecture or data formats—used in for the Internet of Things.

Scalable capabilities

Given the technological underpinnings of industrial edge computers and what they bring to the factory floor, Eastburn said Opto 22 encourages users to take advantage of the capabilities of edge devices to improve performance and lay the groundwork for a more scalable, connected system.

“For example, we see edge computers excel at bridging disparate networks where multiple fieldbuses or IT networks are divided by firewalls or,” noted Eastburn. "They can also shore up legacy devices with an extra layer of security."

He referenced an example of this from an Opto 22 partner working with a food manufacturer in the Philippines. Like many manufacturing operations, this manufacturer had different control systems for production and utilities, and someone at the facility recognized that the company was missing out by not having a way to tune the performance of the whole system. This realization led them to look for way to install a layer of intelligence above the control layer.

“So our partner developed a system to do that using groov EPIC [Edge Programmable Industrial Controller] to give the manufacturer supervisory control of their utilities,” Eastburn said. “Now they’re moving on to what they call the backbone project—joining up all the different control networks into the EPIC network so that they can have all that data available on a common network.”

Replacing Windows

In our discussion for the podcast, both Eastburn and Hougland noted that, as edge computing use expands in industry, they’re seeing users reducing their dependence on Windows PCs. Eastburn said this is happening because users can do it all on their edge computing devices—from having them act as communication servers, to handling database connectivity, to hosting custom applications.

“I wouldn’t say we’re seeing the elimination of Windows PCs in industry,” clarified Hougland. "But they are much more complex devices than are needed in many industrial cases with their update requirements and security issues. That’s why more and more people are looking to eliminate them where it makes sense. But that also means you’ve got to take some of the functionality that was available on the Windows PCs and move it into the edge devices—whether they’re used as a PLC [programmable logic controller], an I/O system, or a data gateway."

Getting back to Eastburn’s earlier point about needing to view edge devices as the connection between OT and IT as the industrial networking architecture becomes more decentralized, Hougland said it helps to view the evolution of edge computing in industry similarly to how we’ve seen our use of the smartphone develop since its introduction.

“When you first got a smartphone, you didn’t ditch your navigation system, your camera, or your music player,” he said. “But as time went on, you used those other devices less and less because you could do it all with your smartphone. We’ll see the same thing with edge computing. As it gets rolled out on to the plant floor and remote sites, people will start seeing the power that’s on the edge device and they’ll see that they don’t need some of these other devices they had counted on previously. If you look at your iPhone today, it doesn’t look all that different from the original, what’s changed is its software capabilities. It was built on a platform that would permit these advances in software to run on the same type of devices. We’ll start seeing the same thing with edge devices—the software is going to take it to new levels we’ve never even dreamed of. So, as you evaluate your edge computing options, look at platforms that have the capability for growth via software as it develops.”

Leaders relevant to this article: