Industrial companies in all verticals and of all sizes are realizing the need to upgrade automation technologies to take advantage of greater system connectivity possibilities and position their businesses for the digital future of industry. While such upgrades may seem daunting, it’s important to realize that a digital transformation does not have to be tackled all at once.

For Bardstown Bourbon Company, a producer of whiskeys and bourbons in Bardstown, Ky., upgrading HMIs is a key starting point.

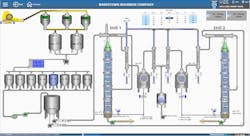

Bardstown Bourbon’s production equipment includes two mash cookers, 32 fermenters, two distillation stills, and nine cistern holding tanks. Its previous HMI system had limited flexibility in terms of data collection, process history, and licensing structure. So, the company began looking for a replacement system that would address these issues, but also allow for the creation of a system architecture that could adapt to Bardstown Bourbon’s changing needs.

After reviewing several options, Bardstown Bourbon chose Inductive Automation’s Ignition platform because it provides a way to communicate with the company’s ERP system. This connection enables Bardstown Bourbon to present operators with a work order request webpage (driven by the ERP system) without requiring them to load a separate application.

Ignition also enabled Bardstown Bourbon to implement a custom batch tracking system and deliver HMI data to mobile devices using Ignition’s Perspective module.

The upgrade happened in the fall of 2019 and took less than a week. During the transition, the new Ignition system co-existed with the previous HMI system.

Roger Henley, Bardstown Bourbon’s plant engineer, said the new Ignition screens were designed to mimic the behavior and actions of the company’s previous HMI screens while also providing new features and improvements.

“Bardstown Bourbon asked us to keep the look and feel of the new HMI system similar to the previous one to avoid retraining of operators on the existing screens,” said Jordan Stoltz, engineering lead for ECS Solutions Inc., the system integrator behind this HMI upgrade.

Batch tracking

The new batch tracking system tracks production batches from mash cooker to cistern. Batch data is collected and logged automatically by Ignition as PLC sequences are executed. For example, as grains are added into the mash cooker, the final delivery weight is captured and recorded in the batch tracking database. When a batch is moved into a cistern, it is electronically linked to a “superbatch” consisting of several batches. Henley pointed out that Ignition facilitates the collection and processing of all events—both manual and automated—related to a batch, logging them to a database for future reference and reporting.

Historical data access was improved for Bardstown Bourbon though the addition of a DVR playback module created by ECS Solutions Inc. This playback module allows historical information from the process to be played back to highlight and troubleshoot process issues. Essentially, it provides an easier way to visualize historical data.

Going mobile

The ability to view data via mobile devices using Ignition’s Perspective module was implemented to extend visibility to supervisors and management. Henley noted that the mobile screens for this project are “read only” to avoid any concerns about remote control of production devices or machinery. The mobile visualizations consolidate information about the distillery’s fermenters, providing a summary of current fermenter status, including temperature, agitation status, and batch time. The responsive design ability of Ignition’s Perspective module allowed ECS to create displays that work on a variety of devices and screen sizes.

To understand how responsive design works, think about this way: On a large screen device, such as a PC, the information is laid out in table structure. On a mobile device, the information shifts into a card layout structure. This provides an intuitive way to view the information that is familiar to any smartphone user. The data is organized in blocks for each fermenter rather than in rows as shown in the PC format.

Informed decision-makingHenley said the new HMI system leverages a much greater amount of historical data on all control points in the system, which allows plant leadership to make more informed decisions. The project also benefits from being centralized, as project modifications are published immediately to all client stations and data are easily accessible by plant personnel based on user permissions. This approach also allows Bardstown Bourbon to collect, store, and review their batch and recipe data consistently. “The ability to historize an unlimited number of data points has changed the way we do business and make decisions,” Henley said.

He also noted that Bardstown Bourbon is the first U.S. distillery to implement Ignition in this manner.

Looking forward, Bardstown Bourbon is planning to implement a batch sequencing engine to automate more of its manual processes. The company also plans to “bring all its inventory control under Ignition,” said Stolz. “They are currently using a separate system to control inventory, and it generates reports for the U.S. Treasury’s Alcohol and Tobacco Tax and Trade Bureau. Our next step will be to bring the functionality of this system over into a new Ignition project.”

Longer term, Henley said Bardstown Bourbon is hoping to use machine learning algorithms to find data correlations that will help them produce highly consistent, better tasting products. “The taste of bourbon is a very subjective thing,” he said. “And there are many different taste profiles. We would like to map these taste profiles with an HPLC (high-performance liquid chromatography) and use that data— along with the distillation data that we are currently capturing—to figure out how to maximize efficiencies and specific taste profiles.”

Leaders relevant to this article: