Since about 2015, when Don Bartusiak, the then chief engineer at ExxonMobil Research & Engineering, publicly advocated for the development of a new, standards-based, open—yet secure—process control architecture, the industry has been working to solve the problem of proprietary vendor lock-in. In 2017, The Open Group, a vendor-neutral technology consortium, launched the Open Process Automation Forum (OPAF), and began work on developing business guides and the Open Process Automation Standard (O-PAS), which is currently on version 2.1

O-PAS version 3.0 is not yet released, but it does promise to deliver a usable system. So, as the standard matures and user labs are set up across the world, the next step is to start deploying O-PAS enabled products.

But it’s a pretty big step to adopt these commercial products, and manufacturers have many questions about how to get started with open process automation. The answers may come from the new Coalition of Open Process Automation (COPA).

COPA is a partnership program started and managed by California-based CPLANE.ai, a provider of cloud infrastructure management, and Collaborative Systems Integration (CSI), a systems integration company in Austin, Texas started by Bartusiak (now retired from ExxonMobil) which is focused on providing technology and services for open process automation (OPA).

COPA’s purpose is to create collaboration among OPA-aligned suppliers that provide hardware and software products which integrate using the O-PAS standard. Currently, the COPA partners include IT and OT technology companies like Phoenix Contact, R. Stahl, SuperMicro, and Codesys, with an expanding ecosystem of suppliers underway to support what COPA founders call “the movement” of everyone working together.

And, to be clear, OPAF and COPA are complementary organizations created to define and promote OPA. “This is not competitive,” said Brandon Williams, co-founder of CPLANE.ai, “It’s a subset of vendors that are ready to demonstrate and implement open products for this market.”

“This is not a splinter activity,” echoed Bartusiak, noting COPA partners are OPAF members. “We’re just trying to capitalize on the commercialization. There are a lot of people standing on the sidelines and waiting for someone to go first. We are stepping up to go first.”

That first step comes in the form of COPA QuickStart, released in June, which is a commercially available product bundled with a six-module training program that allows end users to better understand the technology, the process, and the skills required to manage an OPA system throughout its lifecycle. It encourages end users to learn and experiment with OPA systems (to confirm technical feasibility and to demonstrate business value) so that they can accelerate their adoption of OPA systems.

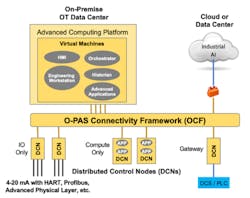

The hands-on modules include: Design (multi-vendor architecture, separation of I/O and compute, etc.), project start-up (configuration, tags, etc.), operations (system management, failover, applications, etc.), evolve (advanced capabilities), secure (role-based access, zero trust device security, etc.), and troubleshooting (remote management, system monitoring, etc.).

Customers can choose from simulated process control applications, such as fired heater, distillation column, or fed-batch fermentation, for example, and they will learn to configure database tags, configure control blocks and HMI displays, and test and tune the control controllers.

“We are hearing that companies want to get started with open process automation now, but a lot of learning has to take place,” Williams said. “The advantage of [the QuickStart] system is it is completely pre-engineered and demonstrates the important features of open process automation, the interoperability of best of class components, and it is inherently secure.”

To that end, COPA QuickStart is intended for end users to learn and experiment with an OPA system. It is not recommended as a production system since it contains early OPA components that will not yet be ready for production workloads. QuickStart will be available to users in Q3 of 2021 and, in general, comes with a year-long commitment for testing and feedback in preparation for production-ready field trials in 2022.

“Industrial manufacturers have repeatedly told me that if O-PAS based systems were available, they would buy them. The COPA QuickStart system is our answer to that challenge,” Bartusiak said.

Leaders relevant to this article: