Considering their importance to the industrial world—delivering electrical power, transferring data, and providing reliable connectivity among end points—cables and connectors don’t often receive the attention they’re due. As much attention is spent on Industry 4.0, digital twins, and other advanced automation technologies, it’s important to recognize that cables and connectors are the transactional backbone of digital transformation. Nothing could be done without them—and that includes the wireless activities that depend on wired infrastructures to seamlessly transfer data to gateways for wireless transmission.

This reality is why the selection of cables and connectors should be treated as critically as the more advanced technologies that often capture more of our attention.

Underscoring the importance of cables and connectors to the digital transformation of industry is the health of this market. Allied MarketResearch projects the compound annual growth of the global cable and connector market will hit 8.3% between 2020 to 2027.

Paying more attention to cabling and connector choices is possibly more important now than ever, as many companies are in the position of needing to upgrade cabling, says Mike Berg, senior business development manager at Panduit. “Many of the plant floors put in Cat5 cabling for Ethernet. But that was a long time ago. The quality of the connection is not up to current standards,” he says. Now, the need to connect controls networks to the enterprise is driving the need for high-performance cabling.

Physical considerations

“When you’ve got 10 or 20 Ethernet-connected

devices within a control panel, you need a comprehensive

design and blueprint around Ethernet

cabling” that accounts for security and

safety, says Berg.

Control panel builders are very diligent about complying with safety requirements, but as connections have grown, “they have all struggled a little bit on how to handle this increase in communications cabling going into the control panel. So, there has definitely been a learning curve,” he adds.

End users and panel builders also need to look at long-term reliability and the ability to “future proof” their cable and connector selections to avoid having to upgrade just a year or two later.

Another trend causing ripple effects in cabling and connector decisions is that mechanical packaging is getting smaller. This creates specific issues for OEMs, says Daniel Koch, senior product manager for the signal division of Molex. “This means the area we have to work with is getting smaller. We can’t just grab things and plug them together as much anymore. The need for smaller components is a big driver in our industry,” says Koch.

Most end users need design assistance and advice on materials selection from a trusted partner such as a systems integrator before they buy. “The value of that collaboration is not having that ‘oh, boy’ moment when you realize something doesn’t work,” says Koch. “With prices soaring on copper and other cabling materials, a trusted advisor can also help you keep costs down, especially when it comes to distinguishing between a choice that saves money in the near term but might lead to prematurely having to replace the cable or connector.”

The number of factors that figure into cable and connector selections are numerous. Here are four key issues to help ensure you select the right cables and connectors for your applications:

- Examine your component media. Start with the basics, such as: What devices do you need to connect? Berg recommends asking: Which switches will be used? How many devices will be connected? Are IoT (Internet of Things) devices in play? What about cameras? What network protocols, such as EtherNet/ IP, Profinet or CC-Link IE are used? Also, make sure your cabling and connector choices match up with existing terminations. Other issues to consider include use of copper and two-pair or four-pair Ethernet cabling.

- Location. When you're shopping for cables, think about the spaces they’re going in. Are you routing from an office environment? Are you going through any riser spaces between floors? You don't want to put cabling in and then find out later you ran through a plenum or a riser space requiring it to be ripped out. Fire safety factors are also key here. If the cabling and connectors will be in an IT cabinet, it is sufficient to use the commercial-grade Ethernet cable that is commonly available. But as you start to get closer and closer to the machine level, you’ll need to consider things like the location of the power source, what separations you might need, and whether you’ll use a cable tray. Berg suggests ensuring you select cabling with the proper jacketing or insulation to fit the application. Then look at the grounding and bonding requirements for the network system.

- Termination performance level. This factor is key to noise susceptibility, says Berg. People tend to overlook the fact that a lot of the copper Ethernet cabling on industrial plant floors is susceptible to electromagnetic interference noise (EMI). The latest cabling—Cat6, Cat6A and Cat8, for example—is much less susceptible to EMI. Going with the most up-to-date version will protect your investment. “That gives you the best possible lifespan on that cabling install,” says Berg.

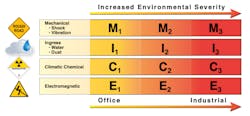

- Harsh conditions. Be sure to consider factors such as shock and vibration, resistance to dust, temperature thresholds, washdown areas, exposure to acids or oil mixtures, and electromagnetic noise. A commonly recommended approach to cable and connector selection is called a MICE analysis, which addresses the mechanical, ingress, climate/ chemical and EMI factors that can impact cabling and connector choices.

We rate our cabling for use in different MICE environments, explains Berg. The MICE analysis helps users determine if a different cable or connector can better survive in their operating environment. It can also be helpful in evaluating the effects on maintenance scheduling.

Harsh conditions can also dictate specific requirements for cables and connectors. For example, an RJ45 connection is susceptible to vibration, but an M12 connector prevents vibration from affecting that Ethernet connection. Likewise, when connecting a high-flex device such as a robotic arm, you will need a high-flex cable. The most rugged cable type is rated as being able to handle more than 10 million cycles. “If you have some type of a moving device on a manufacturing floor that is making a new widget every 10 seconds, you can easily exceed 15,000 cycles very quickly. So, going with a cable that has a rating over 10 million cycles makes a lot of sense in that application,” says Berg.