Though automation technologies have become far more intuitive and open over the past two decades, few people would say they’re “simple.” The intricate details and wide applicability of automation underscore the inherent complexity of such technologies that are required to enable them to function as needed by industry.

Faced with the complexities of automation and the need to develop technologies that are as flexible as possible for industry’s varied uses, Festo has been focusing on making its core automation technologies, such as its I/O and servo drives, as easy to integrate and configure as possible.

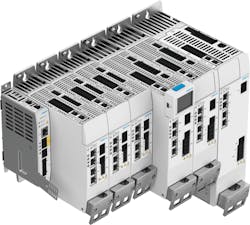

The company recently announced two major developments around its CPX-AP I/O and CMMT servo drives.

Backplane-based remote I/O

Festo’s CPX-AP-A distributed I/O and CPX-AP-I decentralized I/O for use with electric and pneumatic automation systems feature a backplane-based remote I/O system that has been in development for a decade and features a transmission rate of 200 Mbps full duplex. The company’s AP line, which stands for automation platform, is designed to give machine builders the ability to add I/O where required and allow end-users to add functionality as needed.

The CPX-AP-A is a new line of distributed I/O where the modules are attached within a terminal. CPX-AP-I is Festo’s decentralized I/O where modules are connected via cable at distances of up to 50 meters (164 feet) between modules. These AP modules, whether on-terminal or individual, are IP65/67 rated and can be located in cabinets, in clusters around the cell or individually placed as required.

“We’re making a subtle shift in the way this is laid out,” he explains. “When you add devices to an industrial Ethernet network, what you're doing is adding integration points. Each of these devices that sits on the network is an integration point that the controls engineer has to program by adding them to their PLC code and assigning IP addresses to each of them. But many PLC manufacturers offer a very limited number of IP addresses on their more basic controllers. What Festo is doing is making it possible to limit the number of devices on the industrial Ethernet network by reducing all these devices down to just one integration point with a bus interface.”

Rice says the key takeaway from Festo’s work here is that OEMs and end users get one connection or integration point for all I/O and valves. He adds that Festo’s supports for I/O-Link means that this ease-of-integration capability extends beyond Festo devices.

“You can integrate third party devices through our IO-Link master modules and we support all the major Ethernet networks (EtherNet/IP, Profinet, EtherCAT and Modbus TCP),” Rice says.

Festo’s multi-year product roadmap calls for the continued rollout of AP-based PLCs, valves, linear actuators, motors and drives.

Multi-protocol servo drives

As with the CPX AP I/O modules describe above, Festo recently introduced CMMT MP family of multi-protocol servo drives which are configurable for use with EtherNet/IP, EtherCAT, Profinet and Modbus TCP. The drives are rated from 300 W up to 6 kW. Two additional drives—a 9 kW and 12 kW version—are planned for release later this year.

To choose the protocol for a CMMT multi-protocol servo drive, engineers log into the drive using the Festo Automation Suite, select the protocol of choice from a drop-down menu and configure the unit.

“It used to be that when a customer would order the EtherNet/IP version of a drive or the Profinet version or the EtherCAT version, we had to have all of those in stock. With the new multi-protocol version, we don't have to stock multiple versions, we just stock one multi-protocol version and the customer configures it during the commissioning process. A lot of our customers also stock these servo drives because they're working on multiple projects or for spare parts purposes. Now, they can just stock, say, 10 of these multi-protocol versions in their warehouse where they can pull what they need for the project and then configure it as needed. That's really nice for their inventory management as well.”

Worsnopp added that another facet of the CMMT’s updates centers on the servo drives’ processor. He says Festo improved the processor and increased RAM in the drives to allow for additional functionality, such as the addition of an integrated web server.

“This addition of a web server lets the servo drive host a website. So now, when an OEM goes to configure the servo drives, they're going to know what parameter file they have for each of the drives on that machine. This means that every time they duplicate that machine, they can use the web browser for all those duplications. For example, the engineer who's doing the commissioning doesn't have to use our special software to configure those servo drives. Instead, they can just open a web browser, type in the IP address of the servo drive and download the firmware and parameter file and they're done. This speeds up their cycle time and reduces their reliance on our software because they can just use a general web browser.”

Leaders relevant to this article: