Cultured Meat Facility Moves Toward Lights-Out Manufacturing

- Deployed rugged mobile kit with historian software to capture 100+ PLC tags, enabling remote monitoring and real-time visualization of critical parameters like temperature, pH and dissolved oxygen during 28-day production runs.

- Achieved significant progress toward lights-out manufacturing by automating cell cultivation without modifying existing equipment or compromising validation status and cybersecurity.

- Established pathway for higher uptime, tighter process control, reduced manual interventions and lower energy consumption, accelerating cost parity with conventional seafood while maintaining quality standards.

Industry is still a bit away from a true lights-out factory, but there is plenty of opportunity to create a hybrid facility — a dim factory, if you will. This is a facility where automation is extensively used, even running some processes unattended, but humans are still present in reduced numbers for complementary roles.

At Lucid Automation and Security, we saw how this is possible working on what started as a simple study to validate real-time data capture along with a remote visualization strategy to consolidate an eclectic mix of off-the-shelf equipment built on proprietary automation platforms. But after the first 28-day production run, we ended up nudging a San Francisco based cell-cultured meat pilot plant closer to an autonomous, lights-out manufacturing model

The production process

Reviewing the overall process at the cultured meat pilot plant, cell cultivation proved to be the most impactful place to start as the longest-running process step. We saw that fully automating cell cultivation with remote monitoring would be a large step towards the company’s strategic sustainability vision while also establishing the data systems to support quality compliance.

To understand this process better, it’s important to understand that cultivated-meat producers aim to fuse bioprocessing discipline with the efficiency of dark (lights-out) factories. Continuous, sterile operation and stringent quality demands make robust data infrastructure essential.

For this customer, growing batch volumes outpaced the visibility their mixed-vendor control layer could provide. Their engineers wanted live dashboards and historical trends without modifying the commercial-off-the-shelf equipment, rearchitecting the plant network or adding IT overhead.

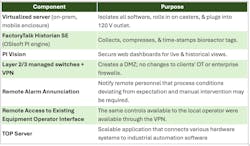

The bolt-on data integrity stack

The quickest way to deliver infrastructure-grade servers and services to the client’s plant network was to deploy our rugged mobile kit. Loading it with Rockwell Automation’s FactoryTalk Historian SE, Software Toolbox’s TOP Server, and Aveva’s PI Vision on virtual servers gave us everything we needed to start secure data collection and real-time trend visualization.

No client software was required to be installed. Authorized users simply connected over a VPN and used a web browser to access the system.

The key parameters logged by this system included: temperature, pH, dissolved O2, pressure, gas-flow rates, batch phase state and CIP/SIP cycles. To do this, we mapped more than 100 PLC and proprietary HMI tags, built interactive PI Vision screens to display trends, P&ID overlays and batch phase. We trained the plant’s engineers on this system in less than a week.

Strategic impact of the system

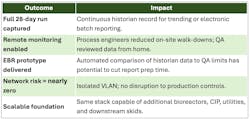

The system performed as expected, providing engineers with remote access to the tags available through a Siemens PLC. A full 28-day run was captured and accessed via the web-based trends and overview graphics.

While this does not immediately enable a lights-out implementation, in just a two-month sprint a foundation had been laid, and a detailed path forward has been identified for incremental improvement towards that goal.

Key achievements of this project delivered:

- A data infrastructure that can be used as the gateway to automated feeding, adaptive control and eventually automatic sampling — the core building blocks of a dim-to-dark factory.

- Higher uptime, tighter control and fewer manual interventions, lower energy per kg, reduced consumables and accelerated cost parity with conventionally farmed seafood.

- Incremental upgrades that can deliver immediate ROI while preserving equipment validation status and cybersecurity posture.

- Specific to the company’s goals of quality and sustainability, adding automated sampling and unlocking access to proprietary HMI data enabled predefined batch reports.

- Collaboration with process development, engineering and QA teams ensured “release-by-exception” would cut decision time, lower inventory costs and boost profitability while maintaining the highest quality standards.

Bill Mueller is the founder and senior engineer of Lucid Automation and Security, an integrator member of the Control System Integrators Association (CSIA). For more information about Lucid Automation and Security, visit its profile on the Industrial Automation Exchange.

More system integrator insights from Automation World:

About the Author

Bill Mueller

Founder and Senior Engineer at Lucid Automation and Security

Leaders relevant to this article: