Once a novelty technology used by a few cutting-edge companies to make part prototypes, 3D printing, also known as additive manufacturing, is now considered a mainstream technology for the factory floor.

A good fit for automotive, aerospace, and medical industries, 3D printing is also the perfect fit for customized work. 3D printing’s early value proposition has always been its ability to shorten production development cycles, with designers and engineers using 3D printing to produce quick-turn prototypes. The technology and materials then evolved to take 3D-printed prototypes and use them in a functioning manner for testing. Now the industry is moving 3D printing into a production support role, leveraging the printers to make jigs, fixtures, or end of arm tools customized for a particular work process.

An example of a company working with this latest stage of 3D printing technology is Ecco, a family-owned footwear company that has been in business since 1963. Ecco owns every step of its traditionally manual shoemaking process. Typically, the sole is molded and then assembled by hand and glued to the upper part of the shoe. Applying the Direct Injection Process (DIP) using a two-component polyurethane mix, Ecco can now create a one-piece 360 degree bond that secures the upper part of the shoe to the midsole.

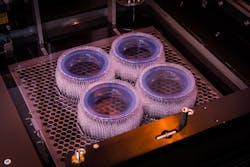

The catch here is that making molds for the DIP process from CNC aluminum comes with long lead times and is an expensive tooling process. It’s not an efficient way to go when multiple designs are being rolled out. So, Ecco turned to Stratasys’ Origin One, a 3D printer that enables flexible production of end-use parts in a diverse range of high-performance materials. Using its Programmable Photopolymerization (P3) technology, an evolution of digital light processing (DLP), the printer achieves accuracy, consistency, detail, and throughput.

In this example, the 3D printer is still playing a supporting role, but that’s a stepping stone to the ultimate goal of production-ready parts. “The emerging area and holy grail of the industry is end use part production for a certain app, skipping the traditional tooling process all together and cutting months out of the cycle time,” said Rich Garrity, Stratasys’ president of the Americas.

In fact, Stratasys already has some early use cases of companies doing this. “We can now print more high performance or exotic materials that can go on a commercial aircraft, for example,” Garrity said. “Better materials and a more repeatable process will have manufacturers using [3D printing] for production.”

Printer selection At this point, there is absolutely no question that 3D printing is coming to the production floor. Now, the question manufacturers need to consider is: What kind of 3D printer to use?

A quick search on the Internet for “3D printers” delivers an acronym alphabet soup: SLA, SLS, FDM, MFJ, DMLS, and numerous others. It’s difficult to know what these technologies are, much less if they are right for your application.

“Generally speaking, deciding which 3D printing process to use comes down to material requirements, such as strength, durability, and temperature resistance, as well as design requirements, including feature size, resolution, part size, etc.,” said Rachel Hunt, 3D printer manager at ProtoLabs, which provides rapid manufacturing of low volume 3D-printed, CNC-machined, sheet metal, and injection-molded custom parts for prototyping and short-run production.

Garrity agrees. “In the 3D printing industry there is no silver bullet. There is not one process that solves all of the applications out there that customers care about. The reality is, it [3D printing] is being used at each stage of product development, design, prototype, and production support. So it depends on first determining what problem you are trying to solve to guide yourself toward the right technology.

Liz Stortstrom, an application engineer at HP adds: “When we get into the space of additive, we’re not talking about replacing all other processes, we want to use it as a tool to complement the processes you’re already using. Figure out how to use it strategically to complement these other methods so you’re getting the best results.”

Back to the basics A good first step is to understand all of those acronyms. Following is a list of popular 3D printing technologies and a rudimentary explanation of what they do, the materials used, and suggested uses:

Stereolithography (SLA) is the first commercialized 3D printing technology, invented by Chuck Hull, 3D Systems' co-founder and chief technology officer, in the 1980s. According to 3D Systems, it uses an ultraviolet laser to precisely cure photopolymer cross-sections, transforming them from liquid to solid. Parts are built directly from CAD data, layer-by-layer into prototypes, investment casting patterns, tools, and end-use parts. Once the SLA printing process is complete, SLA parts are cleaned in a solvent solution to remove any residual uncured resin from the part surface. Cleaned parts are then cured in a UV oven.

- Material—Photopolymers. SLA materials are available in a wide range of mechanical properties and can produce parts with characteristics similar to injection-molded ABS or polypropylene.

- Suitable for applications such as snap-fit assemblies, automotive styling components, and patterns.

Selective Laser Sintering (SLS) is a powder-based 3D printing technology that uses a laser to fuse material layers into a final part. The laser traces the pattern of each cross-section of a 3D design onto a bed of powder. After one layer is built, the build platform lowers and another layer is built on top of the previous layer. This process continues until every layer is built and the part is complete.

- Material—Thermoplastics. According to 3D Systems, SLS really shines when you need durable plastic parts. SLS uses production-grade nylon materials, resulting in durable, functional parts that last.

- SLS is the technology of choice for a range of functional applications, such as jigs and fixtures, housings, snap fits, living hinges and other mechanical joints.

Direct Metal Laser Sintering (DMLS) builds high quality complex metal parts from 3D CAD data. In the machine, a high precision laser is directed to metal powder particles to selectively build up thin horizontal metal layers one after the other.

- Material—Metals. DMP shapes any desired metal part geometry by melting metal powder layer by layer.

- Often used in aerospace applications, it is a good technology for production of small, complex shapes.

Fused Deposition Modeling (FDM) technology developed by Stratasys founder Scott Crump more than 20 years ago, works with specialized 3D printers and production-grade thermoplastics to build strong, durable and dimensionally stable parts with the highest accuracy and repeatability of any 3D printing technology. The printer takes a spool of plastic filament, melts it, and extrudes it on to a tray.

- Materials—Industrial-grade thermoplastics, which makes the resulting parts extremely strong.

- FDM 3D printed parts are in cars, airplanes, medical devices, and more.

Multi Jet Fusion (MJF) is a powder bed fusion 3D printing technology developed by HP. it is similar to SLS in that the printer lays down a layer of material powder on the printing bed, then an inkjet head drops fusing agents onto the print bed of material. No binding, just controlling where in the print bed absorbs more energy from the overhead infrared lamps. The process continues layer by layer until the build is complete.

- Materials—Thermoplastics. MJF’s most common material option is Nylon PA 12, PA 11 powders, but the breadth of available materials has expanded over the years.

- MJF can achieve high strength parts and the overall process is efficient and fast, so this is good for higher volume applications.

Ultimately, the decision as to what technology to use has to do with the process and the materials used. And the materials you choose are based on mechanical properties, strength, flexibility, the environment, and any certifications it may need, such as flammability or biocompatibility, noted HP’s Stortstrom.

“The process influences different factors like strength and isotropy, meaning can you get the same strength vertically that you can horizontally,” Stortstrom explained during a presentation at the Robotics Summit & Expo in May. “That’s a big thing to look out for as you evaluate different technologies.”

At your service If the thought of purchasing a 3D printer still seems confusing, you still have intermediary options. Companies like Stratasys and Proto Labs offer 3D printing services to help organizations with rapid prototyping and production parts.

Stratasys offers seven additive technologies— including its new selective absorption fusion (SAF) technology for components with complex geometries—in its manufacturing on demand service. This gives smaller shops the advantage of cutting-edge 3D printing technology without the operating expense. Larger manufacturers can use a hybrid approach and have some printers onsite, but use the Stratasys Direct service for overflow needs.

“We run banks of our printers and they just send us a CAD file and we produce it for them,” Garrity said.

Similarly, Proto Labs’ online 3D printing service consists of six 3D printing technologies and a broad material selection. The company offers several postprocessing options to improve cosmetics or enhance mechanical properties. With 120 printers, Proto Labs can take a 3D file and turn it into plastic, metal, and elastomeric parts in a matter of days.

Regardless of the approach, one thing is certain: 3D printing is a key technology to modern manufacturing.

“3D Printing will continue to be the ‘Swiss army knife’-like tool that is used when the need arises and it’s exciting,” said Proto Labs’ Hunt. “Fortunately, it is here to help solve many manufacturing challenges from concept to functional prototype to end use part to end of life replacement part. It’s especially going to be a manufacturing tool up-and-coming engineers will know they can leverage. The R&D around materials and printers continues to expand the options on the table.”

Indeed, Garrity feels the next step for 3D printing is to set up an infrastructure that allows adoption at a much bigger scale, meaning the ecosystem of technologies, materials, and software connect to other systems on the shop floor. “We’ll see cells of 3D printers working with automation and robots taking parts o the machine to move it to the next post process for much greater throughput,” he said.

Leaders relevant to this article: