Schaeffler Brings Siemens Industrial Copilot to its Shop Floor

Global automotive parts and industrial machinery supplier Schaeffler has begun using generative artificial intelligence (AI) to drive innovation and efficiency across the design, engineering, manufacturing and operational lifecycle of its products. Schaeffler applies generative AI via the Siemens Industrial Copilot technology to automate engineering and operations tasks on its production machinery.

To support Schaeffler’s engineers with various automation tasks, the Siemens Industrial Copilot is connected to Siemens’ Totally Integrated Automation (TIA) Portal via the open API TIA Portal Openness. The Industrial Copilot helps Schaeffler’s automation engineers generate code faster for its programmable logic controllers (PLCs). With the Industrial Copilot, Schaeffler’s engineering teams can significantly reduce time, effort and the probability of errors by generating PLC code through natural language inputs.

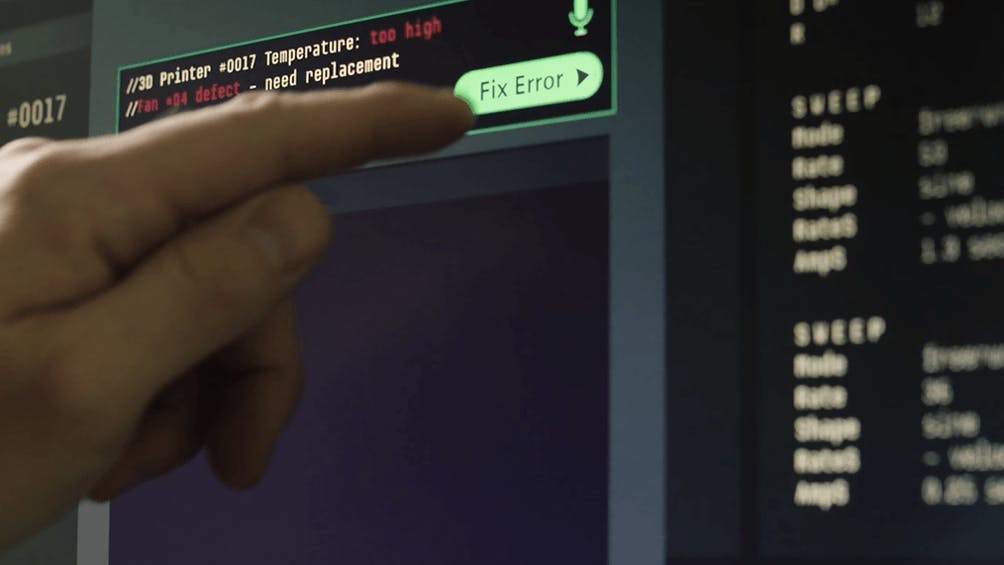

In addition to helping automate repetitive tasks and freeing up engineering resources for higher-value work, Siemens said its Industrial Copilot also helps less-experienced shop-floor employees to grow into engineering roles by walking them through detailed processes to ensure correct actions are taken. Siemens explained that, by connecting Industrial Copilot to the TIA Portal, the generative AI assistant has access to all relevant documentation, guidelines and manuals to assist shopfloor workers in identifying possible errors. These capabilities also enable maintenance teams to identify errors and generate step-by-step fixes more quickly.

Siemens Industrial Copilot will also be used to assist Schaeffler’s operations from the planning phase to validation, generating unit tests of function blocks and continuously monitoring the equipment to optimize machine performance.

“This is the beginning of a new era. In the past, we had to speak to machines in their language. With the Siemens Industrial Copilot, we can speak to machines in our language,” said Cedrik Neike, member of the managing board of Siemens AG and CEO of Siemens Digital Industries. “In few years, AI will be omnipresent in industry. Siemens and Schaeffler are frontrunners, joining forces to make generative AI industrial grade.”