How to Calculate Overall Equipment Effectiveness: A Practical Guide

Why this article is worth reading:

- Learn how OEE directly translates operational inefficiencies into lost money and time. Using a concrete bottling example, it shows how a machine theoretically capable of producing 28,800 units per shift might only produce 9,000 sellable units (31.25% OEE), helping you quantify exactly where your production losses occur and their financial impact.

- Get insights into OEE's three trackable components (Availability, Performance, Quality) with specific calculation methods. This article It shows you how to identify whether your losses come from downtime, slow cycle times, or quality issues to provide a clear roadmap for targeted improvements.

- Clear up the confusion around efficiency versus effectiveness using a standardized approach that explains why you should analyze full weeks rather than individual shifts, how to handle planned versus unplanned downtime, and how OEE integrates with other improvement methodologies like Lean and Six Sigma.

There is a lot of confusion out there about OEE (Operational Equipment Effectiveness) and about the words efficiency and effectiveness. Let us look at these things in an objective and clear manner.

Is OEE just a nice-to-have? No, it is a simple yet powerful roadmap that helps production floor people and management to visualize and eliminate equipment losses and waste.

OEE is not a fad. First of all, OEE has been around for decades in its elemental form. The words efficiency and effectiveness have been around longer, but have only been used in a confused manner in the last decade or so. To start, we have to make a clear distinction between effectiveness and efficiency before we can discuss OEE.

Effectiveness is the relation between what theoretically could be produced at the end of a process and what actually came out or was produced at the end of the process.

If your machine or system is capable of making 100 quality products an hour, and it makes only 70, then it is 70% effective, but we do not know how efficient it was, because nothing is said about what we had to put in (how many operators, energy, materials, etc.) to get the 70% effectiveness.

So if a machine or system runs 50% effective with 1 operator and becomes 65% effective with 2 operators, the effectiveness goes up 30% (yes, 65 is 30% more than 50…) but its efficiency dropped down to 50%, based on labor!

The same goes for yield or more commonly known as quality (basically saleable product). If you are bottling a beverage, all filled, labeled and capped bottles could theoretically be perfect, so the quality would be 100%. But if you throw away half the filled bottles because of packaging or material defects, your yield or quality is only 50%. In this example you would be 100% effective but only 50% efficient.

A simple example of an OEE application

Basically OEE is about (as the name says) effectiveness: it is the rate between what a machine theoretically could produce and what it actually did. So the fastest way to calculate it is simple: If you take the theoretical maximum speed (for example 60 products per minute) you know that at the end of a 480 minutes shift there should be 28,800 units.

1 shift = 8 hours = 480 minutes

Maximum production speed = 60 products per minute

480 x 60 = 28,800 units

Then we need to count what we produced at an end point in the production process such as what’s on the pallet going to the warehouse. If there are only 14,400 good products on the pallet your effectiveness was 50%, right?

Not rocket science so far.

The A-P-Qs of OEE

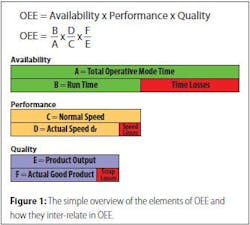

Why does the OEE formula in Figure 1 include availability (A), performance (P) and quality (Q)? What do these words mean and what value do they bring? They’ll help us find where those other 14,400 products that should have been on the pallet disappeared to.

OEE raised the bar and moved us away from the traditional efficiency calculation as a measure of production line output that was easily manipulated to show mediocre lines running at efficiencies up to 150%.

Here is the power of OEE. OEE, when broken into its three main components, is going to track down where we lost it. Every day that we run 50% OEE, we can lose units in different ways, and every loss has its own cost structure.

If we lose 14,400 products because the machine ran flawlessly, with no quality loss but at half the maximum speed, that’s completely different from producing 28,800 products at full speed, and then dumping 14,400 out-of-spec products into the landfill.

Effectiveness is:

- Making the right thing – the right product or SKU at the right speed (Performance)

- Making it the right way – no rework, no defects, no waste (Quality)

- Making it at the right time – producing as planned, keeping the machine up and running, minimizing time losses (Availability)

So how do we find out what we lost and where? And how do we prevent it from happening in the future?

OEE Availability

Going back to the bottle example, let’s track down a normal day. A standard shift takes 480 minutes. Our operators take 10+30+10 minutes in breaks as well as do 2 changeovers of 35 minutes each and lose 60 minutes of machine downtime during the shift. The rest of the time the machine is in the running mode.

Breaks = 10 minutes morning + 30 minutes lunch + 10 minutes afternoon = 50 minutes

Changeovers = 2 x 35 minutes = 70 minutes

Machine downtime = 60 minutes per shift

Total = 180 minutes lost time

This means we lost 180 minutes and there are only 300 minutes left to be effective. Even if we run the rest of the time at full speed with no quality losses, we can never be more than 62.5% effective during this shift. This ratio we call ‘Availability’ or how time is used.

480 minutes – 180 minutes = 300 minutes

300 ÷ 480 = 62.5% Availability

Let’s see how we spent that 62.5% of our time that is available …

OEE Performance

Let us also assume our packaging system has an ideal cycle time or takt time of 1 second per bottle, which is 60 bottles per minute. (Takt time, derived from the German word Taktzeit which translates to cycle time, sets the pace for industrial manufacturing lines.)

This means in the remaining 300 minutes, the machine or system can make 300 x 60 bottles = 18,000. So if at the end of this shift the machine would have made 18,000 bottles during the time it was running, it performed at 100% speed. If production would be at a slower speed, let us say the cycle time would be 1.5 seconds, it would slow down the maximum speed by 2/3, and thus its performance would become 66.7%. The actual output now at 66.7% performance is 12,000 bottles.

300 minutes @ 1 second per bottle = 300 x 60 bottles = 18,000 units

1.5 seconds per bottle = 1 ÷1.5 = 2/3 = 66.7% Performance

66.7% x 18,000 bottles = 12,000 units

Running at 66.7% performance in this case equates in time to losing another 300 x 33.3% = 100 minutes or the line ran on average 2/3 x 60 = 40 bottles per minute.

If at this point all output would be within specification or saleable, what would be the effectiveness?

From the 480 minutes we lost 180 minutes in ‘not running’ and 100 minutes due to ‘too slow a cycle time’; so (480-(180+100))/480 = 41.7% so far.

(480 minutes – (180 minutes + 100 minutes)) ÷ 480 – 41.7% Efficiency

OEE Quality

Whether this is the actual effectiveness depends on how many bottles were within specification. If from the 12,000 bottles, there were 3,000 out of specification, then the quality rate of those bottles was (12,000-3,000)/12,000 = 75% or converting to minutes would be 3000 bottles / 60 bottles per minute = 50 minutes lost due to quality.

(12,000 – 3,000 defects) ÷ 12,000 = 75% Quality

3,000 bottles ÷ 60 bottles per minute = 50 minutes lost Quality

In other words, we lost 180 minutes by not running; from the remaining 300 minutes we lost 100 minutes by slow running; from the remaining 200 minutes we lost 50 minutes making scrap. As a result the line yielded 150 minutes of perfect running at quality and at rate.

Theoretically we could make 480 x 60 = 28,800 bottles. At the end there were 9,000 bottles that were saleable, so the Overall Equipment Effectiveness was 31.25%.

9,000 ÷28,800 = 31.25% OEE

Availability (62.5%) x Performance (66.7%) x Quality (75%) = 31.25%

Why time equals money in OEE

OEE is purely time based (time converted), but since 1 takt time equals 1 bottle, OEE can be calculated in bottles for ease of use. Most operators will not say ‘Today I ran at a takt time of 1.5 seconds but instead “today I ran 40 products per minute” — which is the same thing. Likewise, “I stopped for 5 minutes” is the same as “I lost 200 potential bottles I should have made”.

OEE helps to create this kind of awareness; with operators, with engineers, with logistic departments, and with anybody else involved in the value adding process. It gives a common language to everybody involved in manufacturing and leads to effective and efficient improvements.

The straightforward approach to OEE

OEE and its basic approach have been around for decades in other industries and have recently moved into the packaging area. Although the concepts are fairly simple, their definitions and application have varied considerably, preventing any ability to use them as benchmarks and performance tools within and between plants, let alone between companies. The idea is to present a common definition and straightforward spreadsheet format to bring about clear, common approach.

A practical definition of OEE

OEE is the Overall Equipment Effectiveness of a defined production process during the defined operative period or mode in which all activities related to production, personnel and inputs are accounted for during all producing or dependent activities within a defined scheduled time or operative mode time. The defined production process is the start and end boundary under review such as depalletizing to palletizing or making it through to warehousing.

OEE is defined as the product or cost function or interplay of all availability or uptime of the operative mode multiplied by the performance or actual resultant production speed (from actual dialled rate and ramping rates) divided by the normal or steady state speed and then multiplied by the quality or the output of quality product divided by the input of the critical component or aggregate of all the inputs (components consumed, lost, reworked, destroyed or unaccounted for during the production process). For a diagram, please refer back to Figure 1, page 30.

Quality is a fraction that is 1 minus the waste (waste and rework). Rework is usually considered within quality, but is the most difficult to segregate out. Quality does not typically relate to defective components not staged to the production line, but once staged to the production line they have to be considered. This forces out pre-checks, because once it hits the production line, there are time and impacts to the ongoing production process such as removing and replacing staged defective products, materials and supplies.

Scope of OEE analysis

Although OEE could be done on a machine-by-machine or product-by-product basis or shift-by-shift bases it is usually the amalgamation of one week’s or one month’s production of a given size and product (by machine or line), because looking at smaller slices may not give statistically relevant data for decision making. Trends or specific comparisons could be done, along with looking at a month’s worth of production runs of the same product, family of products or extremes of product sizes and formulations.

Looking at less than 10,080 minutes (one week) of operating time is not significant in and of itself for decision making, but may be adequate for trends and verifications of a decision implemented earlier to insure positive directions or to ensure the anticipated results are being achieved.

The reason for this definition of operative mode is to capture all activities required to ensure the production process could be carried out. Some companies in the past hid their changeover, PM, holidays, training and cleaning by doing it in the so-called unscheduled production time or dumping it on a particular off time, but really it is part of the nature of the production process.

The production scheduled time is the time period in which allotted defined products are to be produced, but process dependent activities or situations must be done or considered beforehand (such as holidays) to ensure the schedule can be met or be reasonable.

The calendar hours or calendar time are the sum of operative mode activities and potential mode activities that make up a week (10,080 minutes) or month (average 43,800 minutes) or defined period in which the asset as a functioning production element exists in the plant.

If any asset is removed from the process in such a way as to make the process for a given product not viable then the expected OEE number is considered zero.

This also applies to product recalled from the market that is reworked or scrapped. A total recall in reality yields zero OEE for the period that produced the recalled product. A partial recall will only deal with the loss of the defined Lot or Batch within the total, but will depress the OEE for that period considerably.

Any scheduling and labor considerations are considered integrated within OEE. One could expand out from OEE with other ratios such as schedule capability in which labor and scheduling times are evaluated and their interplay is calculated as ratios or costs to operations, but OEE keeps a top line view that fits for the vast majority of industries and conditions in a simple but powerful way.

High OEE numbers are indicative of high schedule fulfillment and optimized labor. Schedule fulfillment and optimized labor are a byproduct of the optimized process. OEE is the roadmap for insight, direction and verification of all other activities such as continuous improvement, lean, six-sigma and upper level accounting information. It gives the correct window in viewing the Cost of Quality.

OEE and the cost of quality

The “Cost of Quality” isn’t the price of creating a quality product or service. It is the cost of not creating a quality product or service (For details visit the ASQ – American Society for Quality).

Every time work is wasted, there is a loss that results in the “Cost of Quality” escalating. When talking about waste, we can define or look at many definitions, variations or types of wastage such as: waste of waiting, over-production, inventory or work-in-process, transport, motion, input defects, producing defective products, unnecessary process steps, delaying

In looking at operations, OEE simply gives the clear and powerful picture window view of the ability to sustain quality production or how availability (time), quality (good product) and performance (speed) interact. The Losses portion is the fraction of the time that is lost due to the inability of the production process to be consistent and under control. These losses relate to time down or downtime, rate losses in the process and the scrap and rework generated during the operative mode.

The operative mode is not only the planned scheduled production time but that time that encompasses the nature of the production process and its supporting activities that are connected, dependent or required to be done to ensure the timely production of the scheduled product. This means that apportioned preventive maintenance, changeovers, cleaning and/or sanitizing are included.

The concept of OEE downtime as understood in availability

For simplicity and order, the downtime of any machine or system can be divided into two parts – planned downtime events and unplanned downtime events.

Planned events can be defined as those events in which no output of saleable product results and which management has control over the timing and extent of the activity; mandates them or the country’s regulations define part or all of them.

Holidays are always mandated activities dictated by management, government or both. One could argue that holidays should be left out, but that is incorrect, since it is a management decision to not use that time during a normally operative mode and it is not proper to slip it into the potential mode.

One can break down planned events into as many categories as one likes. Beware, when holidays are included in the analysis, some days or weeks or months will show depressed numbers and need to be highlighted. Because of this, there is a tendency to not include them. But one should include them as they happen.

One can break down unplanned events into as many categories as one likes, but the most common ones are the unit ops or machines. The unit ops could be further subdivided into primary and secondary machines, zones, faults, etc.

Primary machines (PM) are unit ops that are capital equipment that has a direct involvement in assembling the package such as unscramblers, rinsers, fillers, cappers, labelers, cartoners, case packers, palletizers, etc.

Secondary machines (SM) are minor unit ops that convey, manipulate, collate, inspect, code or mark the package such as conveyors, combiners, dividers (when separate from a primary unit op), coders (laser, inkjet, impression, etc.), checkweighers, X-ray, Gamma inspection, independent fill, cap or label detection, rejection units (independent of the major unit op, etc.

Most companies, especially companies with no or poor ability to identify unplanned downtimes or losses, should use the OEE macro analysis and use the lumped or aggregate estimate number until improved data acquisition approaches the estimate number. All times should be in minutes not hours, with precision down to a tenth of a decimal, for a more granular view of the problem.

One can also look at unit ops as VE (value enabling), VA (Value Producing or Value Added) and NVA (no value added, such as a conveyor that simply needs to get product from point A to point B without inducing any quality defects).

Learn more about OEE:

About the Author

Paul J. Zepf

M.Eng. P.Eng., CPP Zarpac, Inc.

Leaders relevant to this article: