To mimic the dexterity of human hands, robot grippers have undergone significant advancements to pick and place a variety of products ever more deftly. Many of these advances were based on giving robot grippers a softer touch when it comes to moving fruits, baked goods, and other less-rigid materials.

But what about injection-molded and 3D-printed parts and components with complex geometries or smooth and less angular products that may not have a surface area suitable for picking by existing grippers? With the rise in custom part production accelerating with the wide availability of 3D printers, this is an increasingly common issue facing part manufacturers.

Adding to this, in many injection-molding processes, parts fall out of the injection molding machine into a catch pan. While this is fine for many parts, those with curved forms can be damaged by this drop.

Another issue that must be managed by robot grippers in such applications is the separation of the sprues (through which the molten plastic flows into the mold) from the parts.

Arburg, a manufacturer of machines for plastics processing based in Lossburg, Germany, faced these issues during development of a new plastic part—an arched handle—for the company’s ThermoLift dryer and conveyor equipment used to handle the plastic granules used in injection molding. The main production challenges for this handle included a requirement that it be positioned at a 15 degree angle in the mold and it needed to be free from aesthetic defects.

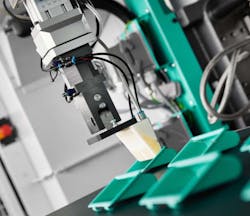

Arburg decided to address these problems in-house by creating a custom gripper for its MultiLift robotic system. To do this, the company used its Arburg Plastic Freeforming (APF) process to manufacture an application-specific gripper that can remove injection molded parts with complex geometries gently, without marring their surface. Arburg accomplished this by combining a hard housing with a soft membrane, which is connected directly to the robot arm.

The gripper features a form-closure grip mechanism inside a thermoplastic polyurethane membrane, as well as a hard housing made of a polycarbonate/acrylonitrile-butadiene-styrene copolymer. The gripper operates by making the soft membrane expand via the introduction of compressed air into the gripper’s ducts, while the hard housing ensures the gripper retains its shape.

The APF process delivers tiny droplets of material and positions them on a part carrier so the material being deposited maintains maximum mechanical strength. According to Arburg, this ability to combine multiple materials is unique and gives designers the freedom to create 3D-printed parts with both rigid and flexible characteristics.

Companies in this Article

Leaders relevant to this article: