Slogans like “safety first,” “safety is no accident,” and “prevention is better than a cure” may be well-worn cliches, but when it comes to industrial and manufacturing safety strategies, few truer phrases apply.

Automation may take a few human workers off the factory floor, but remaining personnel—as well as all equipment and machinery—require protection. Fortunately, there is a wide array of safety devices available that target specific applications in the discrete, batch and continuous processing industries.

The first step to safety

Before choosing and deploying safety devices, be sure to get a comprehensive picture of your operations. According to Robert Mosher, business manager, safety at Rockwell Automation, the first step you should take is to perform a risk assessment.

Mosher says, “A risk assessment is used to identify hazards, estimate the severity of the risk and the likelihood of that risk occurring, as well as how easily it could be avoided. Once the risk is understood, then steps can be taken to mitigate that risk. This process is repeated until all hazards are sufficiently mitigated.”

Mosher also points out that the best solution is to design the hazard out of the machine or process. However, this is not always possible. In such cases, “various safety devices can be used to mitigate the risk,” he says. “The risk assessment will determine the performance level required of the safety measures used.”

According to Eismeier, the most important consideration when integrating safety devices is to determine if the device has the appropriate capabilities for the application to which it is being applied.

For example, if an application requires a Performance Level (PLe) Cat 4 device per ISO 13849-1, is the device capable of that level of performance?

Travis Holley, machine safety services manager at system integrator Polytron adds, “For any type of manufacturing, the characteristics of the safety devices must combine to allow each safety function on the machine or line to meet or exceed the Performance Level required (PLr), a measure which is determined by an ANSI, ISO or RIA risk assessment process. Factors in establishing the PLr include the severity of harm, the frequency of exposure to harm and the probability of avoidance.”

The next factor to address is: Can the device withstand the environment in which it will operate?

“Most devices are compatible with general light manufacturing environments,” says Eismeier. “However, washdown environments, dusty, explosive or other rigorous environments all require additional environmental considerations if the device is to survive.”

Lastly, Eismeier notes the importance of determining if the device suits the functional need of the application.

Safety device types

Industrial safety devices range from basic to complex. Choosing which type to use depends on the application. Following are the most common machine safety devices:

- Machine guarding/hard guarding involves placing a physical barrier on or around a machine. This barrier prevents workers from coming too close to the machine and/or touching potentially dangerous parts of it.

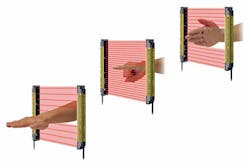

- Safety light curtains create a sensing beam or screen of light across a machine’s access points. If a person or object interrupts the beam, the screen triggers an alert to cease the interruption.

- Safety controllers are described by Keyence (a supplier of sensors, barcode readers and measuring instruments) as verified safety devices consisting of circuits and software. Designed to meet certain safety standards, safety controllers monitor other safety devices and shut off power when a hazard is apparent.

For any type of manufacturing, the characteristics of the safety devices must combine to allow each safety function on the machine or line to meet or exceed the Performance Level required, a measure which is determined by an ANSI, ISO or RIA risk assessment process.

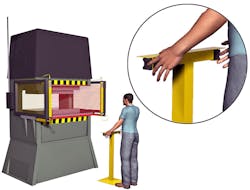

- Two-hand controllers ensure hands are clear of dangerous mechanisms, as they require personnel to use both hands to initiate and maintain machine functions. They are viable for use on machinery with high-force closing movements such as hydraulic presses, stamping machines and cutters.

- Indicator lights, such as bright LED lights, are available in single-and multi-color options to provide visible indication of a machine’s operating functions as well as safety status. Similar to LED indicators, modular tower lights provide visible status of machinery from all angles and at greater distances.

- Safety laser scanners, which are functionally similar to light curtains, use infrared laser beams to scan its surrounding area two-dimensionally. The invisible beams act as a protective field. If a person or object enters the field, the scanner detects the event and generates a change in its signal output.

- Interlock switches prevent machine operation or startup in an unsafe situation such as when a door or guard is open, according to Keyence. Installed on safety doors, fences and guards that separate workers from hazards, they can also prevent doors or guards from opening while the machine is in operation.

- Enabling devices initiate a particular safety function when a user squeezes or releases a switch in a handle grip, similar to a joystick. In contrast, e-stops are button switches that allow workers to stop a machine by pushing the button. Where enabling devices can activate a variety of safety functions, e-stops initiate only one, e.g., stopping the machine.

Another example— trapped key interlock switches—is a cousin to the safety interlock switch. It relies on mechanical locks and keys to control access to gates, guides and/or doors on active machines.

Other common safety components include enclosures, fuses and fuse holders, circuit breakers, intrinsically safe isolators, relay modules, surge protectors, safety mats, edges and bumpers, as well as wire ducts and tubing.

Choosing the right safety device

Though the process for designing a safety system is largely the same regardless of the system being implemented or vertical application, there are some distinct differences to consider.

For example, Eismeier notes that in batch processing applications—such as chemical mixing, water/wastewater or food processing—handling of materials that are explosive, caustic or biologically harmful “often requires safety measures such as specialty fire monitoring systems and gaseous or liquid chemical detectors. These types of technologies are more common in industries typified by process hazards rather than discrete hazards that tend to be more mechanical in nature. Similarly, the process to design such safety systems and the logic to implement them can be more complicated.”

Mosher adds, “One thing about batch manufacturing that needs to be taken into account is how often change-overs are required and the need to access the machine during those changeovers. The more often a particular part of a machine or process needs to be accessed, the more likely that hard guarding will not be the best option and either safety interlocks or presence sensing devices may be required. Also, special consideration needs to be made to ensure that the machine cannot be inadvertently started while a person is in the machine conducting the change-over. For example, a trapped key interlock switch can be configured to ensure that a predetermined sequence of events takes place or that hazards have been reduced before an operator becomes exposed to them.”

Noting that light curtains are often used where frequent access is needed, Mosher notes that it is “critical that a light curtain of the appropriate length and resolution be selected and that the light curtain is located at the appropriate distance to ensure that a person falling through the light curtain cannot reach the hazard before the hazard has time to fully stop.”

Each machine and each process is different and requires a particular solution. That is why a risk assessment is required for each case.

Mosher adds that, if a person is on the inside of a light curtain area, care must be taken to make sure that the machine cannot then be started. In some cases, this requires placing a second set of light curtains perpendicular to and between the machine and the first set.

For process manufacturing applications in general, Holley recommends that “safety devices must be able to withstand environmental factors such as dust, washdown and extreme temperatures. Many machines in process manufacturing have an inherently high run-down time. The use of non-locking safety switches on guard doors could allow access to these hazards. Guard-locking safety switches can be implemented to keep individuals out of the hazard zone until the machine has achieved a safe state. When selecting the appropriate guard-locking safety switch, it’s important to follow industry standards that require the device to be a power-to-unlock type, unless specified otherwise by the risk assessment.”

Safety tips

The most frequently cited safety tip from system integrator experts is to never skip the risk assessment step.

Mosher adds, “Each machine and each process is different and requires a particular solution. That is why a risk assessment is required for each case. An outcome of the risk assessment is the performance level of the safety devices needed. Once you know the performance level required, you can select the appropriate device.”

Holley notes the importance of “periodic functional testing of the safety control system. This testing will help identify faults and failures before a critical demand is placed on the system.”