Less Danger, Lower Costs--ACA.HF Monitors Alkylation Acid

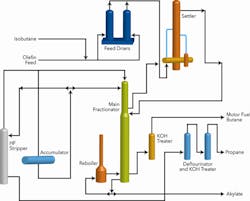

The system dramatically lowers personnel exposure as well as costs and delays in online monitoring of hydrofluoric acid (HF) by replacing two conventional methodologies for HF monitoring, manual sampling and costly Fourier Transform Near Infrared (FTNIR) analysis.ACA.HF provides real time monitoring of HF, and water concentrations within an alkylation process, helping to maximize yield rates of the unit. Traditional approaches to HF monitoring involves taking manual samples and analyzing them in a laboratory, but this sampling offers limited accuracy and exposes lab workers to toxins. More recent FTNIR techniques are highly accurate, but adaptation for real-time online monitoring is complex and costly due to the acquisition and installation as well as maintenance-heavy nature of the method. In the development of ACA.HF, Invensys Operations Management teamed with a leading refiner to create and validate new online HF monitoring models that deliver highly reliable results at significantly lower acquisition and operating costs. The new ACA.HF Advanced Measurement system costs about half that of an FTNIR system and requires minimal maintenance, because its core components are built from rugged materials long proven in industrial HF applications. Based on established industry methods, estimated mean time between failures (MBTF) of the solution exceeds 29 years. There were, in fact, no maintenance costs in the first year of implementation at the development partner's refinery..The monitoring models run in the new Foxboro PAC System controller, which provides a cost-effective and easy-to-setup application environment. Advanced analytical software contributes to precise control by, in essence, creating a virtual spectrum that is directly analogous to that produced by a traditional FTNIR. "The solution brings together proven corrosion-resistant sensor technologies, advanced mathematics and software development, and existing ECS components and data flow," Dickson said. "Collaboration with our customer brought us expertise in the alkylation process in general and HF needs in particular. Bottom line, we had all the resources needed to build a reliable, repeatable system to translate density, conductivity and pressure data into real-time HF monitoring."This unique measurement and control solution contributes to asset excellence by minimizing the potential for corrosion. At the same time, it supports environmental and safety excellence by eliminating the need to bring operations and laboratory personnel into close contact with HF, a common concern in manual sampling. Also eliminated are delays around permissions and timing to access the alkylation unit, and training and safety garb costs associated with manual methods. Additional benefits include new insight into when to activate feed driers, which over the long run can amount to significant energy savings. The ACA.HF solution is an integral component of the company's InFusion Enterprise Control System, as it shares a common communications and applications development environment that enables the solution to be part of a larger plant and enterprise control, information and decision support system."Real-time results provides operations new ways to predict alkylate production accurately," said Brian Dickson, Vice President and General Manager, Field Devices, Invensys Operations Management. "This means that operations gain insight into which orders to pursue and where to spend money—and perhaps most importantly, offer reliable output numbers that corporate can use to increase sales activity.""The biggest champions of this solution are the people who have tried it," Dickson said. "It helps that ACA.HF comes with a team dedicated to rapid, safe installation and commissioning."