OPC Over DNP Links Remote Pumping Stations

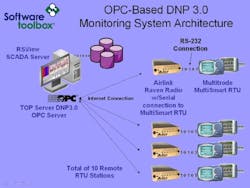

In the water and wastewater industry, it is a constant challenge to get data from remote pumping stations. Supervisory control and data acquisition (SCADA) applications are filled with mixed communications topologies: serial, Ethernet, serial over radio, Ethernet over radio, private radio, public cellular. The list of variables seems to go on forever. Add in variable weather conditions that make communications intermittent, and you have a tough challenge.Traditional communications protocols that may be used over serial and Ethernet often aren’t up to handling the environmental issues and insuring that when data does get through, it’s accurate. Enter the Distributed Network Protocol (DNP). This protocol has been around for many years in the utilities and water treatment industries, and is designed to be robust with heavy error checking in every data packet. The protocol also allows for unsolicited messages from Remote Terminal Units (RTUs) whenever data changes within a dead-band, thereby lowering communications traffic over radio links. In a recent application in the western United States, a Software Toolbox systems integrator deployed OPC with DNP for one of its clients. The integrator implemented the TOP Server DNP 3.0 Protocol OPC Server from Software Toolbox, which is located in Matthews, N.C., in a complex application involving Rockwell Automation RS-View software and MultiTrode Multi-Smart pump controllers operating as RTUs. The TOP Server OPC Server was operating as a master on a DNP 3.0 protocol network. The TOP Server OPC Server talks to the MultiTrode intelligent pump controllers on 10 different pumping and lift stations scattered across the large site.What makes this application particularly unique is that communications to the RTUs was done via AirLink Cellular radios operating over the Verizon Wireless cellular data network. Using the TOP Server’s built in Ethernet Encapsulation feature helped avoid the need for separate virtual communication port software and made setup and commissioning that much easier. Flexible timeout configuration settings allowed the TOP Server DNP 3 OPC Server to be tuned to response times of each cellular station on the network. The DNP protocol’s ability to report changes by exception was used to minimize bandwidth utilization on the cellular network. When the TOP Server OPC server starts, it does an initial poll of each RTU station and then listens for changes to be reported by the RTUs as they happen. Dead-band settings in the RTU insure that only changes of significance are reported. The RS View human-machine interface (HMI) system gathers data from the pump stations regarding number of starts/stops, pump run times, motor voltages and currents, and current pump status. The RSView system also logs data gathered from the RTUs using RS-SQL.Other features of the TOP Server OPC Server that reduced commissioning time and increased reliability include protocol level diagnostics that allow the system integrator to capture actual live data packets if there are communications problems. The ability to “copy & paste” devices and then reconfigure and change the driver settings at runtime, without restarting the server, also saved a great deal of time. Extensive runtime diagnostics are available from TOP Server for display on the RSView HMI station to indicate current communications status and number of successful reads or writes. The OPC server automatically recovers from communications errors and will resume communications to devices when they come back online after a loss of communications. For more information on OPC solutions from Software Toolbox, visit www.softwaretoolbox.com/opc.