Mars 2020 Rover To Use Curiosity Framework

One of the perks of this job is getting to see a number of highly interesting presentations at technology conferences. Some of those presentations are very specific to applications of automation technology, while others are generally interesting to a science and technology oriented audience.

At the 2013 Siemens Automation Summit, I had the opportunity to hear Doug McCuistion, former director of NASA’s Mars Exploration Program. McCuistion was featured at the Siemens Automation Summit due to Siemens involvement in the Curiosity rover project. Siemens PLM software, including NX CAD, NX CAM, NX CAE and TeamCenter were used to design, simulate and assemble the rover before any physical prototypes were built.

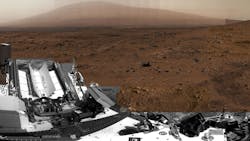

Less than a month after the Siemens Automation Summit came news that NASA’s next rover will head to Mars in 2020 to look for signs of past life, collect samples that could one day return to Earth, and demonstrate technology for future human exploration of Mars. The 2020 rover will be similar to Curiosity to “help minimize costs and risks and deliver a rover that can accomplish the mission objectives,” NASA says.

The part of NASA’s comment about the 2020 rover being built using Curiosity’s framework is a huge confirmation of Curiosity’s success.

As McCuisition noted at the conference, “In 5 months, we were able to determine that Mars contains all the elements needed for life to exist.” Finding this kind of evidence was the primary goal of the Curiosity mission. “Like Earth, Mars is covered in water,” McCuistion said. “It’s just in ice form. We’ve seen it snow on Mars and we found evidence of three different water events: ground water, lakes, and running streams.

In his presentation, McCuistion offered a number of pieces of advice for the engineers and manufacturing managers in the audience based on his experience with the Curiosity rover. Some of that insight included:

• It’s critical to recognize the difference between technology challenges and engineering challenges.

• When it was decided to go fully redundant with Curiosity’s avionics systems, this created a packing problem—fitting so many components in such a small space (which should sound familiar to many engineers’ issues with device footprint issues). McCuisiton noted that Siemens PLM helped NASA overcome the design issues associated with this problem.

• In describing how quickly both the rover technology and NASA’s ability to manage the rover’s landing on Mars had increased over the years, McCuistion noted that, in the course of 15 years, NASA advanced from the 10kg Pathfinder to the 1 metric ton Curiosity.

• Several complex actuators were used to move, steer and operate Curiosity and its tools. In all there are 30 actuators on the rover of six different types.

• 33 states and nine countries were involved in development and creation of Curiosity. “These projects create high tech jobs globally,” he said.

Summing up his presentation, McCuistion offered a final piece of advice to the audience: “If you believe in what you're doing, the enthusiasm will take you there.”

Watch the NASA video "Seven Minutes of Terror" below describing the engineering used to manage Curiosity's difficult Mars landing.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: