3D printing technology has been around since the 1980s, but in the past 10 years the market for this technology has been undergoing a dramatic change. From its primary applications as a means to create small plastic models and prototypes, 3D printers are now commonly used to create full-scale clothing, prosthetics and electronics products. But its biggest potential application is industrial products, says Alex Chausovksy, senior principal analyst, industrial automation, IHS.

Speaking at the 2014 IHS Industrial Automation conference, Chausovsky noted that industrial machinery production—which represents $1.6 trillion of the $3.8 trillion global industrial capex spending in 2013—is the area to be most dramatically affected by advancing 3D printing technology. Because 3D printers can now work with materials such as titanium, steel, aluminum and copper, the technology is poised to be a game changer when it comes to making parts for industries such as automotive and aerospace.

The increased ability for innovation in design, Chausovsky said, means that companies armed with 3D printing technology can “work from function rather than fit,” allowing changes to be made far more quickly than ever before. This translates into faster speed to market for new products and reduced development costs, as far less material—40-70 percent less—is required to make a product using 3D printing technology versus traditional methods.

Dramatic market changes as a result of 3D printing are expected to impact the machine tool and plastics injection molding first, noted Chausovsky. To illustrate his point, Chausovsky pointed out that current modern manufacturing methods to create an end-of-arm robot tool cost $10,000 and take about four weeks. Using FDM (fused deposition modeling) techniques, however, the cost is only $600 and can be done in 24 hours.

Current methods used to manufacture “motors and drives, sensors, hydraulic drives and valves are all threatened,” Chausovsky said. “We’re on the cusp of seeing new ways to produce motors, using deposition versus lamination. Leading motor manufacturers are experimenting with this now.”

Chausovsky added that variable frequency drive heat sinks created with 3D printers using lattice structures have been proven to do a better job of heat dissipation than many current types and are smaller in size.

Potentially the biggest change that 3D printing could bring to the manufacturing industry is a restructuring of intellectual property rights. To illustrate this point, Chausovsky spoke about how a replacement for an old seatbelt bracket on an Airbus A310 aircraft was recreated using 3D printing. A CAD model of that bracket did not exist, Chausovky said, so it was reengineered by digitally scanning an existing bracket to create a 3D CAD model, thereby allowing a replacement part to be printed.

This process could have a huge impact on after-market sales of parts, Chausovsky said. “Manufacturers will have to think about IP (intellectual property) in a different way. They may need to move from selling physical parts to selling CAD files for customers to print.” For this business model to be effective, however, the “price point will need be appealing to stop customers from just scanning a product and reverse engineering it themselves.”

Chausovsky likened this potential market transition to what occurred in the music industry with Apple iTunes. It was Apple’s model of selling songs for 99 cents that made it appealing enough for people to buy the music legally rather than risk threat of prosecution through illegal downloading.

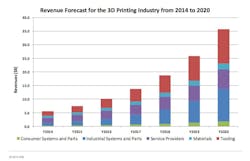

Though this outcome is not yet a reality today, industrial parts manufacturers need to begin thinking about this. As 3D printing patents start to expire, it means that high costs of the technology to date will soon start to be less of a factor. Chausovsky said the 3D printing market is expected to grow 30-40 percent a year for the next 5 years. Current 3D printer suppliers such as 3D Systems, Stratasys, Arcam, EOS and ExOne will soon be joined by the likes of Hewlett-Packard, Canon, Epson, and Xerox —all of which have announced their intent to enter the market. Other companies looking into the market include 3M, Google, Microsoft, Apple, Samsung, IBM and Amazon.

With this level of concentrated industry focus, the current limits of 3D printers—such as high printer and material costs, as well as speed and size limits—will likely be overcome in the not-too-distant future.

If the 3D printing industry progresses as Chausovsky predicts, industrial part IP as we know it today could disappear in 10 years. Which raises an even bigger question — what will be the impact on innovation?

Alex Chausovsky will be at The Automation Conference 2015 to speak further about 3D printing and its impact on industrial automation. Register to attend at www.theautomationconference.com.

Leaders relevant to this article: