Automating Industrial Business Processes with Business Process Modeling Notation

In our previous blog we posed a broad question, where do operators fit with current manufacturing technology trends? More specifically, we asked:

What if we could map out each manufacturing process, execute that process in software and have it delegate tasks to operators to complete via a simple automated task list user interface on a mobile device?

The premise centers on how technology adoption can bring improvement in business process and foster the upskilling of people at the same time, all in the name of improvements in efficiency and implementing Industry 4.0.

Mapping out manufacturing processes and executing them in software

We’ve explained previously how business process modelling provides a solid framework for digital transformation of your business.

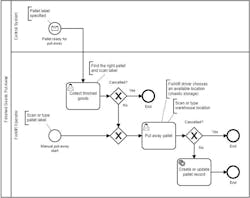

Business process modelling notation (BPMN) is a method used to set up a system to execute a process, assign tasks, and automate system integration based on a human readable design.

BPMN has been executing business processes for some time. Many of these processes have become second nature to us, for example, in financial sectors or human resources. The same principles can also be applied to industrial use cases, enhancing quality processes, increasing data integrity, or improving response times to maintenance issues to unlock efficiencies in new ways.

Integrating systems and machines has been possible for a long time but this approach is complex and costly when trying to exclude people from the process entirely. In many use cases, it’s simply not possible yet. Including people in the integration ensures operators fit with current manufacturing technology trends.

This is core to our approach in orchestrating machines, systems, and people by making use of BPMN mapping and execution in software. It allows us to automate a process inclusive of user tasks and provides a more gradual pathway towards lights-out manufacturing.

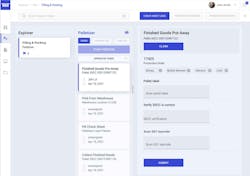

So, how do we orchestrate people? With an automated task list.

The BPMN 2.0 notation includes articulation of user tasks which allows us to push the right tasks to the right users and user groups at the right time during the execution of a business process.

Example 1: Finished goods put-awayThis approach can be used for other use cases like delivering raw materials to a production line or consuming raw materials against a production order.

Our sister company, SAGE Automation, delivered Intelligent Transport Systems (ITS) for a busy freeway in Melbourne, Australia. Commissioning required testing of every piece of equipment, including numerous speed signs and hazard signals, and documenting everything that was tested.Using a solution developed by Nukon, ITS engineers could manage repetitive tests, documenting every step. As the commissioning stage has a defined series of steps, we were able to delegate tasks to operators (including third-party operators), escalate tasks to a supervisor if there was a failure and prove compliance to the client in one printed report.

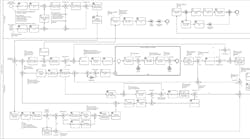

Example 3: Picking and packing shipping containers

To demonstrate how far we can take this concept, consider the process of fulfilling a sales order by picking and packing a shipping container from a warehouse, booking shipping with logistics, unloading and loading containers on trucks, and preparing a container for packing.

This type of process can be highly complex and involves many user roles including logistics, sales, crane operators, and forklift operators. BPMN can orchestrate all these user roles, delegating user tasks at the right time in the process, as well as interfacing and orchestrating ERP systems for sales orders, and WMS systems for picking stock.

A change from no integration to full Industry 4.0 lights-out manufacturing is an enormous, complex, and costly undertaking for most businesses.

Including people in the technological advances allows for a more gradual, iterative approach that’s made possible by executing BPMN process maps in software and delegating tasks to users. As businesses grow and more technology becomes available more of those user tasks can be refined, simplified, and possibility fully automated.

In an upcoming article, we’ll explain how this same approach is highly intuitive for users and enables up-skilling users for more advanced Industry 4.0 roles.

Kim Fiddaman is a Senior Consultant at Nukon, a SAGE Group brand. SAGE is a certified member of the Control System Integrators Association (CSIA). For more information about SAGE, visit its profile on the Industrial Automation Exchange.

About the Author

Kim Fiddaman

Senior Consultant, Nukon

Leaders relevant to this article: