Rural Alaskan Villages Rely on OPC for Critical Power Systems

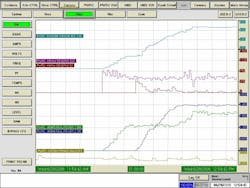

Electric Power Systems Inc. (EPS), in Anchorage, Alaska, has been providing systems to power producers and power utilities in rural Alaskan villages for several years. EPS typically uses Wonderware’s InTouch human-machine interface (HMI) package and includes the Trend Historian trending packages from Canary Labs, based in Martinsburg, Pa., with every system it sells.

Canary Labs uses the OPC standard to connect with the InTouch software to collect data. EPS has deployed Canary Labs solutions on dozens of installations in critical power systems that utilize wind, diesel and hydroelectric energy. Canary Labs has been a key component in ensuring the successful integration of different power sources for a lower cost, more reliable energy solution for remote Alaskan facilities.

With earlier systems, there was no way to track or repeat intermittent problems. Trever Kudrna, of Electric Power Systems states, “We now collect all possible data and track everything for the users for a minimum of a one-year period. We can now find problems that we could not locate any other way.” It is critical to quickly find and resolve any problems, because these rural Alaskan villages are solely dependent on their local power systems. There is no power grid in much of rural Alaska, so if the local power system goes down, there is no electricity.

Historian solves problemA few years ago, in Cordova, Alaska, at a three-megawatt Hydro unit, there was an intermittent problem that would occur once every two or three weeks. The position of a nozzle would keep moving unexpectedly. Initially, there was a lot of finger pointing and guessing that the problem ranged from the programmable logic controllers to the control logic itself.

With the help of the Canary Historian, the problem was determined to be a defective hydraulic manifold. Without the complete history records, it is very difficult to troubleshoot and resolve a problem such as that. The Canary trending solution made it relatively easy, which is why EPS puts Canary Labs solutions in every system.

For more information on OPC-based historian solutions from Canary Labs, visit www.canarylabs.com.