This project was completed to fulfill the requirements for a course on Mechatronic Design at Carnegie Mellon University. The basic premise of the project was to design and build a system that can efficiently play Connect Four against an opponent. There were restrictions on size (approximately 36" W x 22" D x 36" H), and the device had to be portable, using a dedicated power supply for electronics. To prepare the machine for gameplay, the chips could either be dumped into a container in the machine or stacked on the playing surface to be picked up by the machine.

Project Name: Connect Four Player

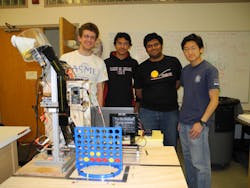

Students: Matt Eicholtz, David Chang, Balu Nair, Sai Yamanoor

Project Details

The required performance metrics included:

• The mechanism had to be capable of inserting game chips into all 7 slots in the board.

• The mechanism must take no more that 20 seconds per move.

• The mechanism must retract from the neutral area (12" x 8" area surrounding board) between turns.

• The mechanism must display some level of game-playing intelligence (i.e., no random moves).

• The mechanism must transmit its moves to the opponent via RS232 serial protocol (9600 baud rate, no parity, 8 bits per message, 2 stop bits, no flow control).

Equipment Used

• NI LabVIEW 2010 with embedded module for ARM microcontrollers

• Stellaris ARM LM3S8962 evaluation board

• NXP1768-based MBED microcontroller

• 12V dc motor

• Connect Four game set

• 24V, unipolar stepper motor

• Flexible spring-beam coupling

• Two solenoids

• Infrared sensor

• Blue and pink LEDs

Watch the CMU Connect Four team of Matt Eicholtz, David Chang, Balu Nair and Sai Yamanoor have way too much fun with a video of their project inspired by “The Office” (below).

Automation World would like to thank National Instruments for connecting us with the CMU Connect Four Team to make this "Engineering School Innovations" installment possible.

Leaders relevant to this article: